Laser Process Technology

Scantech has been at the forefront of laser technology research and development for over three decades. Our Process Technology Section leverages extensive expertise and cutting-edge lab facilities to help customers create optimal and environmentally responsible laser applications.

Additionally, our specialists provide computational modeling, technical support, and failure analysis to enhance Scantech’s research and operations across the full range of laser technology applications—from initial design to advanced manufacturing processes.

application lab

to assembly

Material Processing with Laser

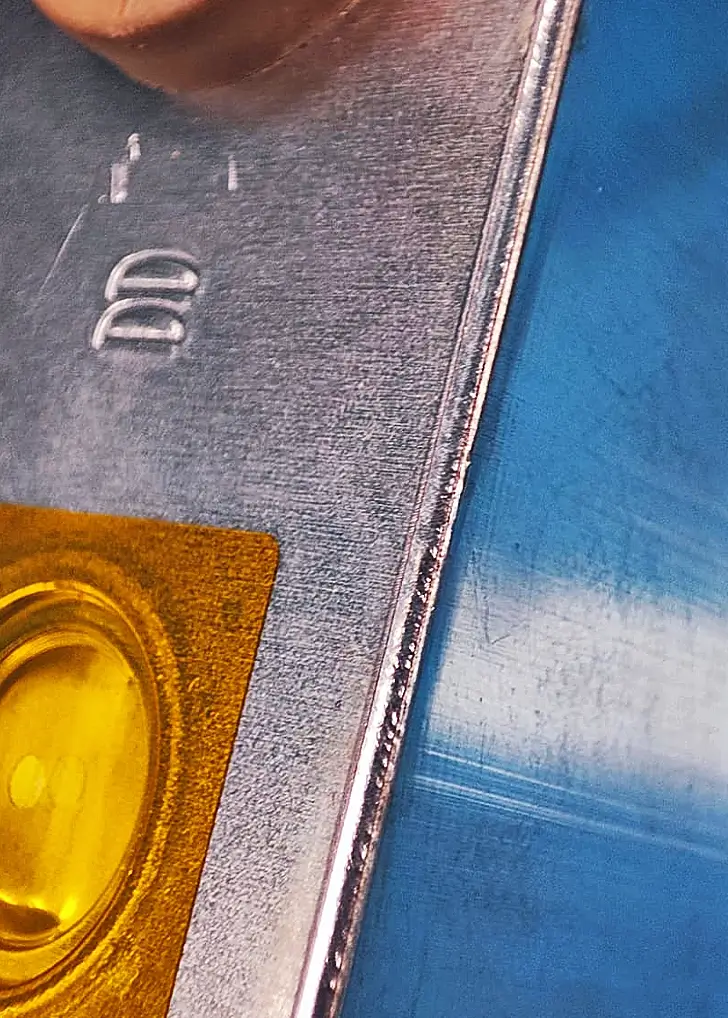

In our Application Lab, material processing with lasers involves a variety of activities using different types of lasers, including fiber, CO2, UV, Nd:YAG and green lasers, with power ranging from 1W to 6kW. We focus on optimizing laser parameters for a wide range of applications such as cutting, drilling, welding, marking, hardening, cladding, cleaning, and scribing. Our goal is to ensure precise and efficient results tailored to diverse industrial needs.

Moreover, our engineers and Materials Technology specialists leverage their process expertise, on-site experience, and lab resources to drive continuous improvements in operational safety, cost efficiency, and environmentally responsible practices across our facilities.

design & development

The Application Team at Scantech supports precise equipment design, repair, and maintenance to ensure reliable and safe performance across all our operations. Our team specializes in selecting the optimal wavelength for each material, fine-tuning machine parameters, and providing customized application guidance.

Meanwhile, the Design Team at Scantech focuses on real-time computational modeling and engineering to optimize application processing. Inputs from our engineering team ensure that each system is designed and produced with high precision and quality, adhering to various manufacturing standards.

Manufacturing & Assembly

At Scantech, our Manufacturing and Assembly processes are central to delivering top-quality laser systems tailored to meet diverse industrial needs. Our state-of-the-art facilities are equipped with advanced technology and staffed by skilled professionals dedicated to precision and excellence.

We utilize cutting-edge machinery and technology to manufacture high-performance laser systems. Our manufacturing process involves rigorous quality control at every stage, from sourcing premium materials to executing precise machining and assembly. By adhering to strict standards and incorporating innovative techniques, we ensure that each component meets our high-quality benchmarks.

The assembly process at Scantech is a meticulous and detailed procedure where our expert technicians bring together the various components of our laser systems. Each system is carefully assembled, calibrated, and tested to ensure optimal performance and reliability. Our assembly team follows stringent protocols to ensure that every system is assembled to exact specifications, with attention to detail that guarantees seamless operation.

By integrating advanced manufacturing techniques with a thorough assembly process, we deliver laser systems that are not only technologically advanced but also durable and dependable. Our commitment to excellence in manufacturing and assembly ensures that our clients receive products that exceed their expectations and deliver exceptional performance in their applications.

- Laser Products Research & Development

Scantech’s leading position in laser technology for the automotive, aerospace, and other sectors is well-earned. Our legacy includes pioneering laser solutions for various applications. Through our dedicated Research and Technology teams, we continuously develop innovative products and solutions to drive our clients and the industry forward.

Our Technology Center works closely with other Scantech research team. Additionally, our headquarters hosts an exceptional product development team focused on advancing laser technology innovations across multiple industries.

- Research & Technology Center

Scantech’s Product Technology equips engineers and professionals with state-of-the-art resources, including advanced testing, sophisticated modeling, and comprehensive failure analysis. These tools drive the development of cutting-edge laser technology innovations across various applications. In our labs and facilities, the future of laser technology is shaped.

Mechanical Testing

Tools

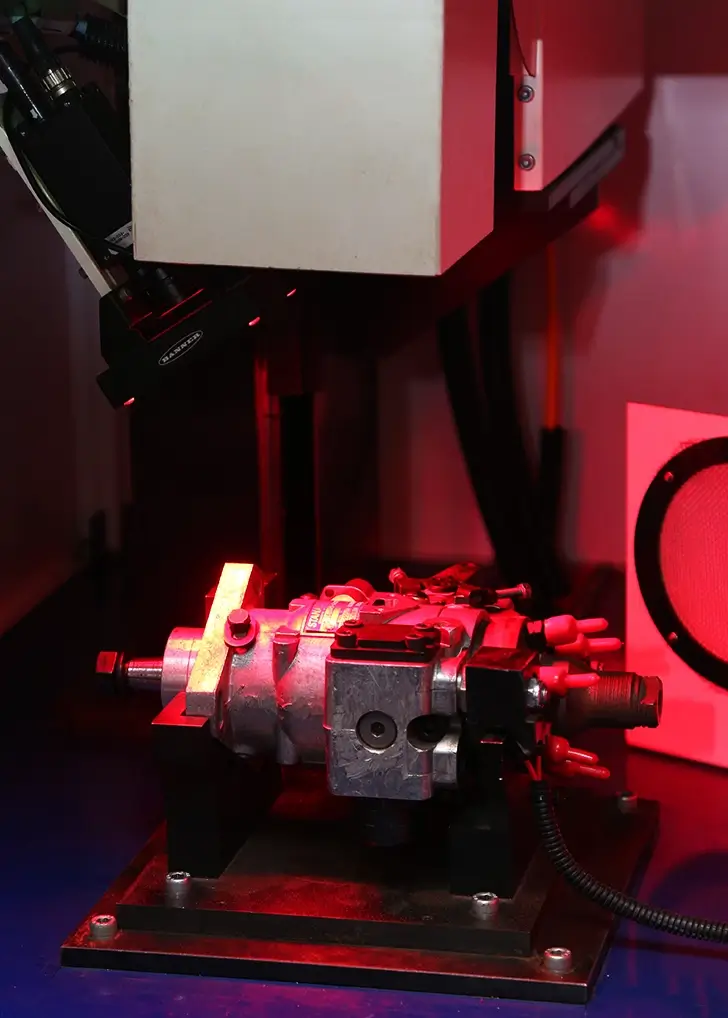

We utilize advanced automated equipment for essential tests, including tensile and hardness measurements. Our facility is equipped with various gauges to measure every micron with precision. Additionally, we have profile projectors, digital, and optical microscopes to ensure comprehensive analysis and accuracy in testing.

Optical & Laser Testing

Tools

We utilize cutting-edge optical and laser testing tools for precise measurements and evaluations. Our facility features advanced instruments including laser power meters, beam quality analyzers, focus finders, and optical apertures. These tools enable us to accurately measure laser power, assess beam quality, precisely locate and adjust the focal point, and control beam diameter, ensuring optimal performance and reliability of our laser systems.

Electrical & Electronics Testing Tools

We use advanced electrical and electronics testing tools to ensure the performance and reliability of our systems. Our facility is equipped with state-of-the-art instruments including oscilloscopes, multimeters, signal analyzers, and power analyzers. These tools allow us to precisely measure electrical signals, test circuit functionality, analyze waveform characteristics, and monitor power consumption. By leveraging these technologies, we can thoroughly evaluate and optimize the electrical and electronic components of our systems to meet the highest standards of quality and performance.