Overview

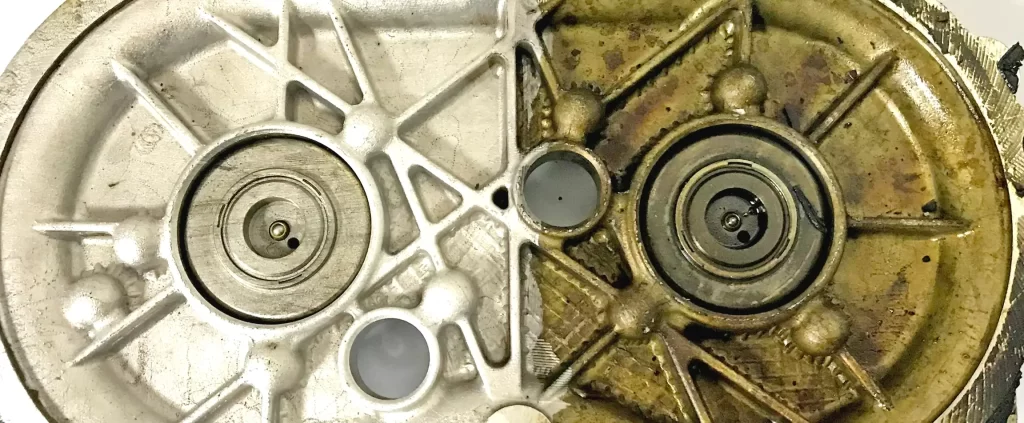

Laser Cleaning is an advanced and eco-friendly technique designed to remove rust, paint, oxide, and other contaminants from metal surfaces without damaging the underlying material. This process is gaining popularity across various industries due to its efficiency and environmental benefits.

Key Advantages of Laser Cleaning:

- Non-Destructive: Laser Cleaning precisely targets contaminants while preserving the integrity of the base material. It effectively removes coatings and residues without causing harm or alteration to the substrate.

- Eco-Friendly: As a green technology, Laser Cleaning does not introduce dust or impurities into the environment. Unlike traditional cleaning methods that may involve harsh chemicals or abrasive materials, laser technology operates cleanly and sustainably.

- High-Speed Operation: Laser Cleaning offers superior speed compared to conventional cleaning methods. The high-intensity laser beam quickly and effectively cleans surfaces, increasing productivity and reducing downtime in industrial applications.

- Minimal Waste: The process generates minimal waste, as the contaminants are vaporized or ejected in a controlled manner. This efficiency contributes to cleaner operations and reduces the need for disposal of cleaning byproducts.

- Precision Cleaning: The laser beam can be precisely controlled to target specific areas, making it ideal for cleaning intricate or delicate components. This precision ensures thorough removal of unwanted materials while preserving the quality of the cleaned surface.

- Safety and Low Maintenance: Laser Cleaning is a safe and low-maintenance option. It eliminates the need for hazardous chemicals or abrasive materials, reducing safety risks and operational costs associated with traditional cleaning methods.

- Versatility: This technology is versatile and can be applied to various materials and contaminants. Whether dealing with rust on steel, paint on aluminum, or oxide on other metals, Laser Cleaning provides effective results.

- Reduced Environmental Impact: By avoiding chemical solvents and abrasive media, Laser Cleaning minimizes the environmental impact associated with surface preparation. It aligns with modern sustainability goals and regulatory requirements.

- Enhanced Efficiency: Laser Cleaning improves operational efficiency by providing a faster and more reliable method for surface preparation. Its ability to clean large areas quickly and accurately makes it suitable for high-volume industrial applications.

- Applications: Laser Cleaning is widely used in industries such as automotive, aerospace, manufacturing, and maintenance. It is effective for tasks such as preparing surfaces for welding, restoring metal components, and removing contaminants before painting or coating.

In summary, Laser Cleaning is a cutting-edge solution that combines efficiency, safety, and environmental responsibility. Its ability to clean surfaces with precision and minimal waste makes it a valuable tool in modern industrial processes.