Laser marking on automotive mirrors involves a precise and non-invasive process where the laser is directed onto the reflective side of the mirror to create permanent markings. This method is particularly advantageous because it generates localized heat, which selectively removes only the top coating of the mirror without damaging the underlying glass or affecting its reflective properties. The result is a durable, high-contrast mark that remains intact over the lifetime of the mirror.

This technology is not limited to automotive mirrors but extends to a wide range of glass-based products, including makeup mirrors, interior decorative mirrors, gift items, and even glass surfaces on wine bottles and mugs. The versatility of laser marking allows it to be applied to various types of glass, depending on their composition and intended use.

Different types of lasers, such as CO2 lasers, fiber lasers, and UV lasers, can be employed for marking glass surfaces, including mirrors. The choice of laser depends on the specific characteristics of the glass, such as its thickness, coating, and material composition. For example, UV lasers are often preferred for marking highly delicate or thin glass surfaces due to their ability to create fine, detailed marks without causing thermal damage. Fiber lasers, on the other hand, are more suited for tougher glass compositions, providing deep, precise engravings with minimal heat impact.

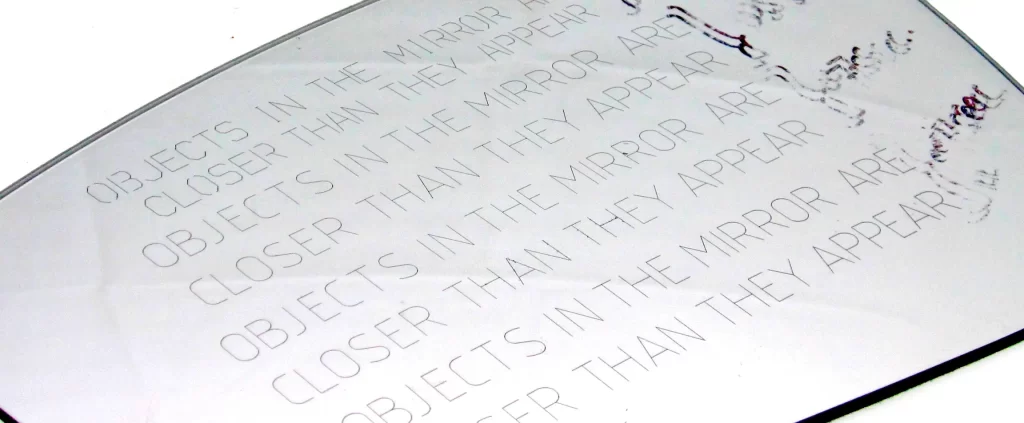

In the automotive industry, laser marking is essential for adding functional and aesthetic details to mirrors. These markings can include logos, serial numbers, safety information, and decorative designs, all of which contribute to the branding, traceability, and customization of the final product. The precision of laser marking ensures that even the most intricate designs are executed with accuracy, enhancing the visual appeal and functionality of the mirrors.

Moreover, laser marking on mirrors offers several operational advantages. The process is contactless, meaning there is no risk of scratching or physically altering the surface of the mirror. This ensures that the mirror retains its integrity and optical quality, which is crucial for both safety and aesthetic purposes in automotive applications. Additionally, laser marking is a fast and efficient process, making it ideal for high-volume production environments where consistency and throughput are key.

Laser marking is also environmentally friendly, as it does not require the use of inks, solvents, or other consumables that could generate waste or harmful emissions. This aligns with the growing demand for sustainable manufacturing practices in the automotive industry and beyond.

In summary, laser marking on automotive mirrors is a sophisticated and reliable method for creating permanent, high-quality markings without compromising the integrity of the glass. The adaptability of laser technology to different types of glass and the precision it offers make it an indispensable tool in the production of automotive mirrors and other glass-based products. Whether for functional identification or decorative purposes, laser marking ensures that the final product meets the highest standards of quality, durability, and aesthetics.