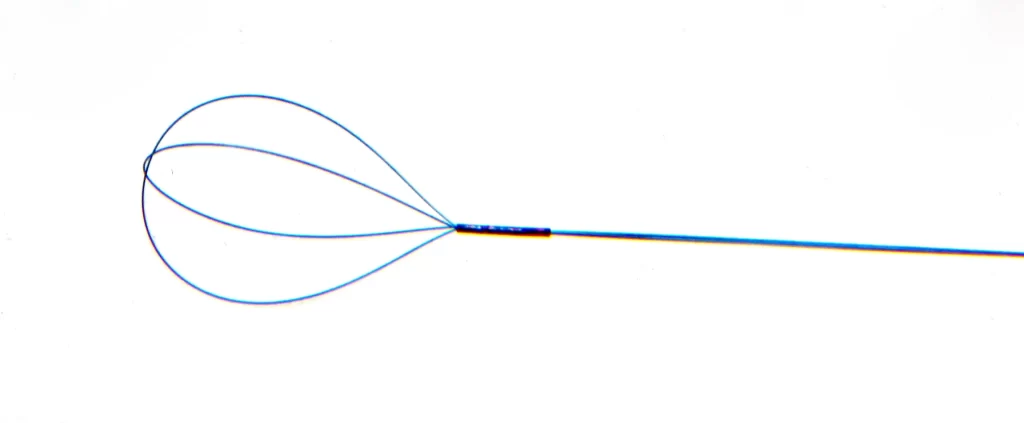

Nitinol, a remarkable shape memory alloy, is ideal for applications requiring precise and complex shapes, such as tipless baskets used in medical devices. Laser welding is the preferred technique for working with Nitinol due to its ability to produce intricate and high-quality welds without the need for fluxes, solvents, or additives. This biocompatible method ensures that the welded components are safe for use in medical applications, including those involving direct contact with internal body parts.

Laser welding offers several distinct advantages for Nitinol tipless basket welding. Firstly, the process allows for the creation of flawless hermetic welds, which are crucial for ensuring the integrity and reliability of medical devices. The precision of laser welding ensures that the welds are clean and consistent, which helps maintain the functionality of the device and avoids potential complications related to weld seam interference.

The cleanliness of laser welds is particularly beneficial in the medical field, where sterility is of utmost importance. Laser-welded Nitinol components are easier to sterilize compared to those produced with traditional welding methods, which may leave residue or require extensive post-processing. The absence of fluxes or other contaminants in the welding process ensures that the surfaces remain non-porous and sterile, making them suitable for high-temperature sterilization processes.

Additionally, laser welding provides excellent control over the weld parameters, allowing for precise adjustments to achieve the desired weld quality. This level of control is essential for producing complex shapes and maintaining the mechanical properties of the Nitinol material. The resulting welds are strong, durable, and resistant to deformation, ensuring that the welded components perform reliably in their intended applications.

The suitability of laser welding for high-temperature sterilization further enhances its appeal for medical device manufacturing. The technique ensures that the welded components can withstand the rigors of sterilization processes without compromising their structural integrity or functionality. This capability is essential for maintaining the safety and effectiveness of medical devices used in critical procedures.

In summary, Nitinol tipless basket welding using laser technology offers a range of benefits for medical applications. The precision, biocompatibility, and cleanliness of laser welds make it an ideal choice for creating complex and reliable components. With its ability to produce high-quality, hermetic welds without the need for additional processing, laser welding ensures that Nitinol components meet the stringent standards required for medical devices. Whether for intricate designs or high-temperature sterilization, laser welding provides a dependable and efficient solution for working with Nitinol and other shape memory alloys.