process

Laser

Cutting

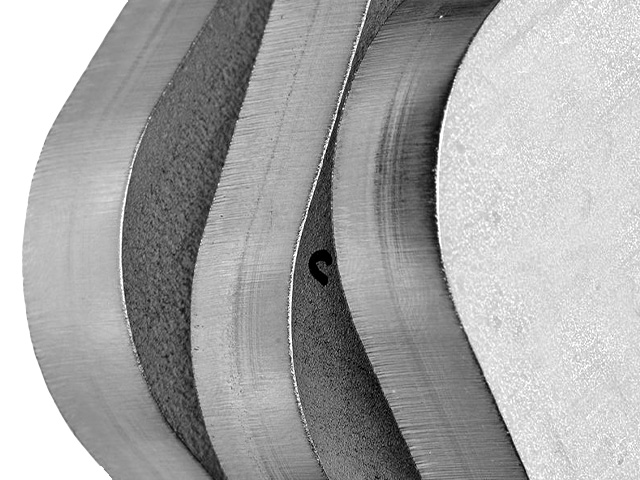

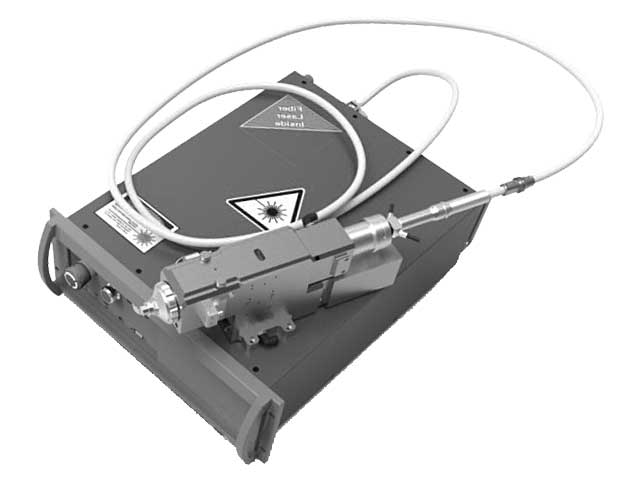

Laser cutting machine is primarily used for industrial manufacturing applications. It can also be defined as a technology that uses a laser, to cut materials. This machine is uniquely designed for cutting various kinds of metals & non-metallic materials.

Cutting metallic & non-metallic materials is possible with the help of laser cutting machine. Some of the essential features of laser cutting machine are high processing speed, reliability, durability, flexibility, high accuracy, outstanding cut quality, high efficiency, excellent beam quality, longer service life and negligible maintenance.

Different Versions of Laser Cutting Machine

Our laser cutting machines are

Understand

ProCut

1000

Finding an affordable and easy-to-use laser-cutting machine can be a challenge. But with the ProCut 1000, you can get a great machine without breaking the bank. This machine has a rigid frame and gantry, making it extremely sturdy and stable. It also has an automatic edge-finding function, so you can easily find the right cutting-edge for your project. Plus, the ProCut 1000 comes with intelligent automatic software, making it easy to use and eco-friendly.

The ProCut 1000 makes it possible for anyone to do professional quality cutting jobs. It is affordable and offers a single-step cutting process, which takes a lot less time than the traditional cutting process.

The ProCut 1000 laser cutter has been designed to be versatile and easy to use, making it a great option for all sorts of jobs, from prototyping to production runs.

The ProCut 1000 is the best budget-friendly laser-cutting machine on the market today with its user-friendly software and easy operating procedures!

Air Cooled

Cooling Type

Work Table

Open/Enclosed

Job Height

Adjustment

Motorized/Manual

Laser

Power | Wavelength | Frequency | Pilot Beam | Power Consumption | Model No. |

20W | 1064 nm | 20 – 200 kHz | 0.3 mW | 150W | 1020 |

30W | 175W | 1030 | |||

50W | 250W | 1050 | |||

20W | 1 – 1000 kHz | 150W | 1120 | ||

30W | 175W | 1130 | |||

50W | 250W | 1150 |

Marking

Scan Speed 8.0 - 12.0 m/s

Minimum Character Height 0.1 mm

Marking Area Options 30 mm², 50 mm², 75 mm², 110 mm², 150 mm², 200 mm²

Z axis Manual 100 mm

Focus Guidance Laser ¹

System Support

Supports Windows 10

USB Control Interface

Format Support

plt, dwg, dxf, bmp, jpeg, cdr

Additional Features

Barcode, Data Matrix Code, QR Code Marking

Database Connectivity ¹

Serializing & De-Serializing ¹

I/O Integration as subsystem ¹

Product Compliance ¹

Operating Conditions ³

Ambient Temperature 0 - 40° C

Humidity 30% - 85%

Utility ³

Input Voltage 110V or 240 V, 10A

Frequency 50hz - 60hz

UPS 2 kVA

¹ It is an add-on to the standard system offered separately.

³ To be provided by the user as per specification

Model

ProCut -

1xxxS

Budget-friendly & single-step cutting process with combined edge decreases the length of cut and low wastage of material.

**All images & specifications mentioned are for reference purpose and are subject to change without notice.

Understand

ProCut

2000

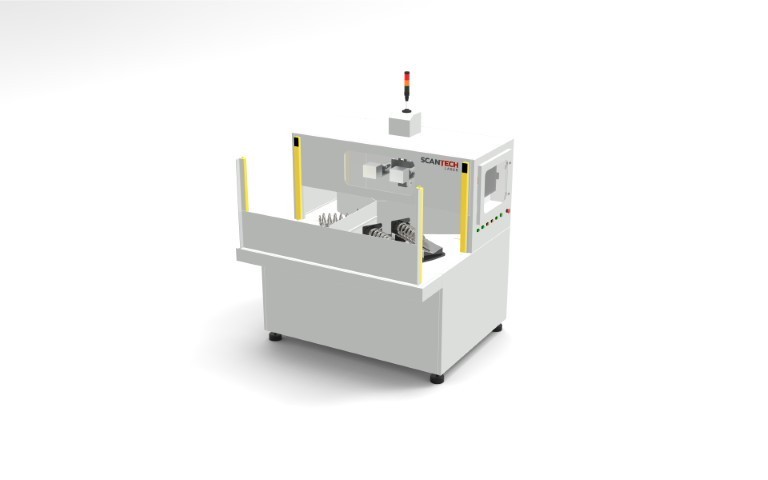

The ProCut 2000 is a top-of-the-line gantry cutter that is both eco-friendly and features an anti-collision head. With its ready-to-use edge-finding function and intelligent automatic software, the ProCut 2000 is perfect for any precision-cutting application. Plus, its enclosed frame ensures a safe and efficient cutting experience.

The ProCut 2000 laser cutting machine is a powerful and eco-friendly machine that is easy to use. This machine is designed for people who don’t have the patience for a manual saw and wish to do their work faster and with more precision.

The ProCut 2000 laser cutter has many features that set it apart from other machines in its category, such as its anti-collision head, rigid gantry, and enclosed frame. These features make it an amazing tool for anyone who wants to get the job done as quickly and efficiently as possible.

Air Cooled

Cooling Type

Work Table

Open/Enclosed

Job Height

Adjustment

Motorized/Manual

Laser

Power | Wavelength | Frequency | Pilot Beam | Power Consumption | Model No. |

20W | 1064 nm | 20 – 200 kHz | 0.3 mW | 150W | 1020 |

30W | 175W | 1030 | |||

50W | 250W | 1050 | |||

20W | 1 – 1000 kHz | 150W | 1120 | ||

30W | 175W | 1130 | |||

50W | 250W | 1150 |

Marking

Scan Speed 8.0 - 12.0 m/s

Minimum Character Height 0.1 mm

Marking Area Options 30 mm², 50 mm², 75 mm², 110 mm², 150 mm², 200 mm²

Z axis Manual 100 mm

Focus Guidance Laser ¹

System Support

Supports Windows 10

USB Control Interface

Format Support

plt, dwg, dxf, bmp, jpeg, cdr

Additional Features

Barcode, Data Matrix Code, QR Code Marking

Database Connectivity ¹

Serializing & De-Serializing ¹

I/O Integration as subsystem ¹

Product Compliance ¹

Operating Conditions ³

Ambient Temperature 0 - 40° C

Humidity 30% - 85%

Utility ³

Input Voltage 110V or 240 V, 10A

Frequency 50hz - 60hz

UPS 2 kVA

¹ It is an add-on to the standard system offered separately.

³ To be provided by the user as per specification

Model

ProCut -

2xxxE

ProCut - 2xxxE

Eco-friendly with anti-collision head. Ready to begin cutting from some place other than the edge.

**All images & specifications mentioned are for reference purpose and are subject to change without notice.

Understand

ProCut

3000

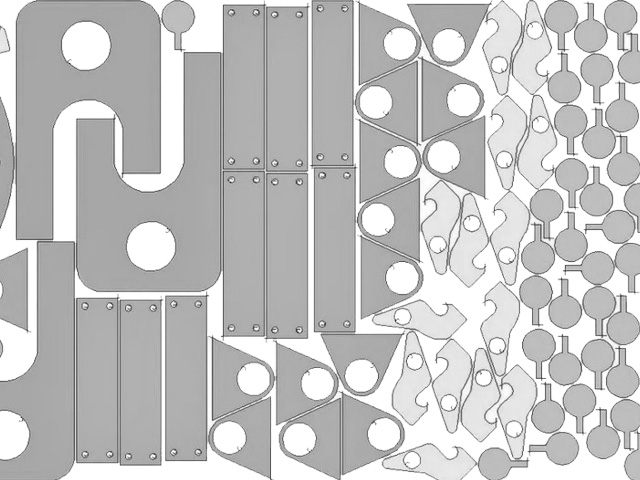

Looking for a fully customized cutting solution? The ProCut 3000 might be just what you need. This powerful machine is suitable for deep-drawn, hydro-formed, tubing, and stamped parts. It features an auto-focus laser head, auto-clamping system, and anti-collision head. Plus, its single-step process makes it very efficient.

The ProCut 3000 was created according to the needs of customers. It is a powerful and eco-friendly machine that can cut and engrave with precision.

This laser-cutting machine has an Auto Focus Laser Head that keeps the laser on the material being cut. The head also shifts automatically when cutting curves, avoiding any misalignment or problems in the final product.

The ProCut 3000 can cut a range of materials such as paper, card stock, plastic, film, cardboard-like material, and glass. There are no limitations to what can be done with this machine!

Air Cooled

Cooling Type

Work Table

Open/Enclosed

Job Height

Adjustment

Motorized/Manual

Laser

Power | Wavelength | Frequency | Pilot Beam | Power Consumption | Model No. |

20W | 1064 nm | 20 – 200 kHz | 0.3 mW | 150W | 1020 |

30W | 175W | 1030 | |||

50W | 250W | 1050 | |||

20W | 1 – 1000 kHz | 150W | 1120 | ||

30W | 175W | 1130 | |||

50W | 250W | 1150 |

Marking

Scan Speed 8.0 - 12.0 m/s

Minimum Character Height 0.1 mm

Marking Area Options 30 mm², 50 mm², 75 mm², 110 mm², 150 mm², 200 mm²

Z axis Manual 100 mm

Focus Guidance Laser ¹

System Support

Supports Windows 10

USB Control Interface

Format Support

plt, dwg, dxf, bmp, jpeg, cdr

Additional Features

Barcode, Data Matrix Code, QR Code Marking

Database Connectivity ¹

Serializing & De-Serializing ¹

I/O Integration as subsystem ¹

Product Compliance ¹

Operating Conditions ³

Ambient Temperature 0 - 40° C

Humidity 30% - 85%

Utility ³

Input Voltage 110V or 240 V, 10A

Frequency 50hz - 60hz

UPS 2 kVA

¹ It is an add-on to the standard system offered separately.

³ To be provided by the user as per specification

Model

ProCut -

1xxxS

Budget-friendly & single-step cutting process with combined edge decreases the length of cut and low wastage of material.

**All images & specifications mentioned are for reference purpose and are subject to change without notice.

Understand

ProCut

4000

If you’re looking for a powerful and accurate robotic cutting machine, the ProCut 4000 is a great option. This machine is an expert in 3D cutting with arbitrary curve cutting and higher accuracy. It also features an autoloader and an automatic edge-finding function. Plus, the anti-collision head ensures safety while in operation.

The ProCut 4000 is the first laser-cutting machine that can handle both top-down and bottom-up finishing. It automates the entire process from the loading of raw material to offloading of completed parts. This automation reduces human error, increases efficiency, and also improves the quality of the end product.

The intelligent automatic software with a two-step process enables auto-loading and robotic operation while also reducing errors in cutting jobs. The machine also has a fully integrated laser alignment system that allows the positioning of the laser head along with auto compensation for wear on moving parts and changing atmospheric conditions.

Air Cooled

Cooling Type

Work Table

Open/Enclosed

Job Height

Adjustment

Motorized/Manual

Laser

Power | Wavelength | Frequency | Pilot Beam | Power Consumption | Model No. |

20W | 1064 nm | 20 – 200 kHz | 0.3 mW | 150W | 1020 |

30W | 175W | 1030 | |||

50W | 250W | 1050 | |||

20W | 1 – 1000 kHz | 150W | 1120 | ||

30W | 175W | 1130 | |||

50W | 250W | 1150 |

Marking

Scan Speed 8.0 - 12.0 m/s

Minimum Character Height 0.1 mm

Marking Area Options 30 mm², 50 mm², 75 mm², 110 mm², 150 mm², 200 mm²

Z axis Manual 100 mm

Focus Guidance Laser ¹

System Support

Supports Windows 10

USB Control Interface

Format Support

plt, dwg, dxf, bmp, jpeg, cdr

Additional Features

Barcode, Data Matrix Code, QR Code Marking

Database Connectivity ¹

Serializing & De-Serializing ¹

I/O Integration as subsystem ¹

Product Compliance ¹

Operating Conditions ³

Ambient Temperature 0 - 40° C

Humidity 30% - 85%

Utility ³

Input Voltage 110V or 240 V, 10A

Frequency 50hz - 60hz

UPS 2 kVA

¹ It is an add-on to the standard system offered separately.

³ To be provided by the user as per specification

Model

ProCut -

4xxxR

Budget-friendly & single-step cutting process with combined edge decreases the length of cut and low wastage of material.

**All images & specifications mentioned are for reference purpose and are subject to change without notice.

ProCut 4000

4000 series With robot does the work on any 3D work piece as per the requirements.

Comparison - Laser vs Alternate

Laser Cutting

Plasma Cutting

Waterjet Cutting

Wire Cutting

Advantages of Laser Cutting

Faster Cutting Speed

High density of energy focused with a small spot size making the material softer at very rapid speed which results in faster cutting.

High Accuracy

Smaller spot size helps to create smaller kerf width results in superior edge finish & better accuracy of ±0.1 mm

Lower Running Cost

High electrical efficiency & maximum material output, resulting in considerably lower running costs.

Low Maintenance

No moving mirrors in the light generating source, reducing maintenance, and operating costs.

Materials that Laser Cuts

Related Solutions

Related Posts

5 Best Features of Robotic Laser Cutting Machines

Both laser technology and robot technology are processing rapidly, with robotic laser cutting machines becoming increasingly popular in the automobile industry. Due to its technolo

Uses Of Laser Cutting Machine For Architectural Models

Laser cutting machines are considered ideal for creating architectural models. There are many reasons why laser machines should be given precedence over other forms of the machine

How To Have A Fantastic Laser Cutting Machine With Minimal Spending

Suppliers and who support other industries with their production technology and precision equipment have several ways of providing their clients with just what they need. The top l

Learn How To Utilise 3D Laser Cutting Machine To The Fullest

Most people who possess laser cutting machine use it for either one or two specific purposes. These machines have a highly versatile nature and they can be used to produce [&hellip