Laser drilling technology

advantages of laser drilling

Non-Contact Process

As a non-contact method, laser drilling minimizes the risk of material deformation or damage, ensuring high-quality results even on delicate or sensitive materials.

High Precision and Accuracy

Laser drilling offers exceptional precision, enabling the creation of micro-holes with tight tolerances. This is ideal for applications in industries such as aerospace, electronics, and medical devices where exacting standards are required.

Minimal Heat-Affected Zone (HAZ)

Laser drilling generates a focused beam of heat, resulting in a very small heat-affected zone. This reduces the risk of thermal distortion, especially when drilling small, intricate holes.

Material Versatility

Laser drilling is highly versatile and can be used on a wide variety of materials, including metals, ceramics, plastics, and composites, making it adaptable to various industries and applications.

types of laser drilling

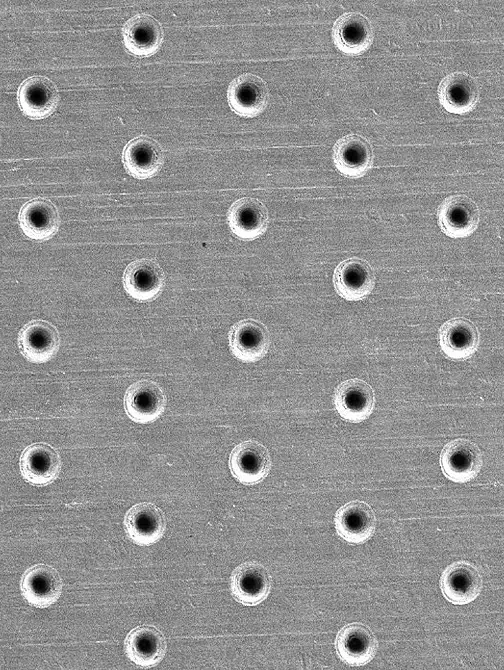

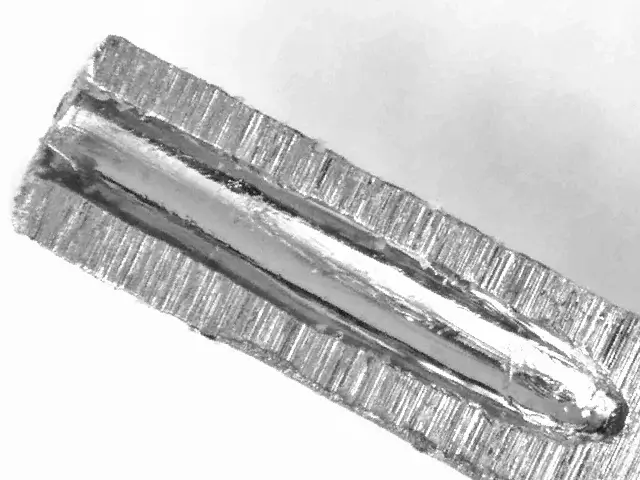

Percussion Drilling

This method involves firing a series of laser pulses at the same spot to gradually drill through the material. Each pulse removes a small amount of material until the hole reaches the desired depth.

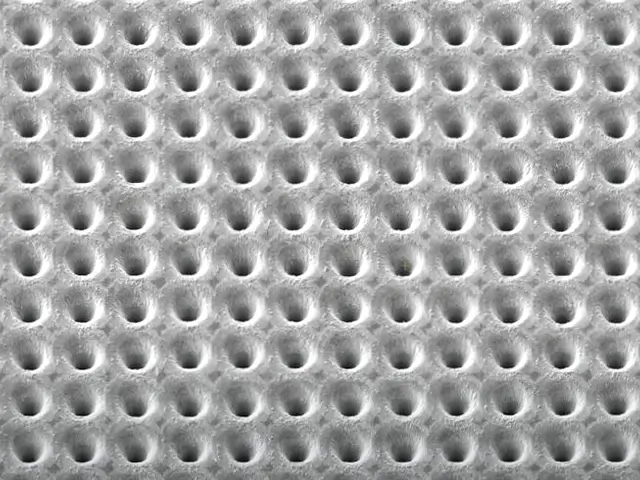

Single-Shot Drilling

A single laser pulse is used to drill a hole in the material in one shot. This method is fast and efficient but is typically limited to thinner materials.

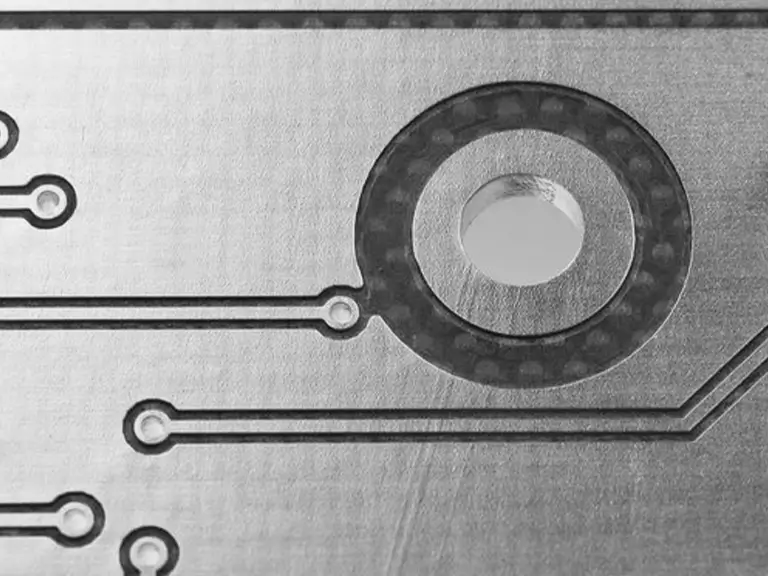

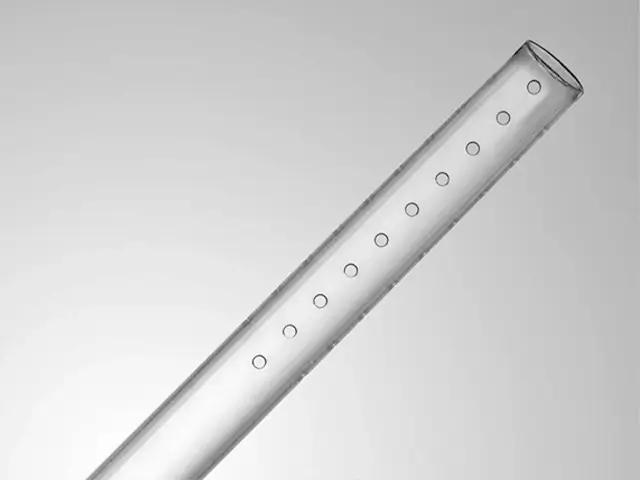

Trepan Drilling

In this method, the laser beam moves in a circular path to cut around the perimeter of the hole, removing material in a manner similar to mechanical drilling. It allows for the creation of larger diameter holes with smooth edges.

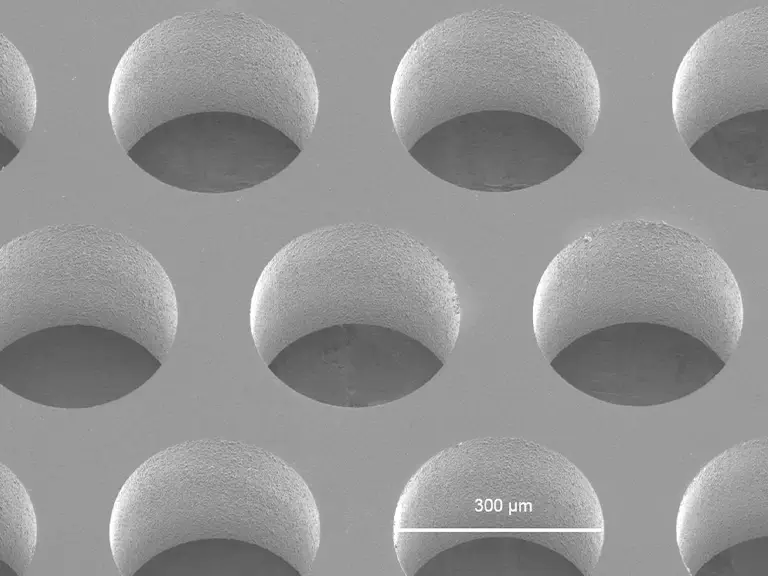

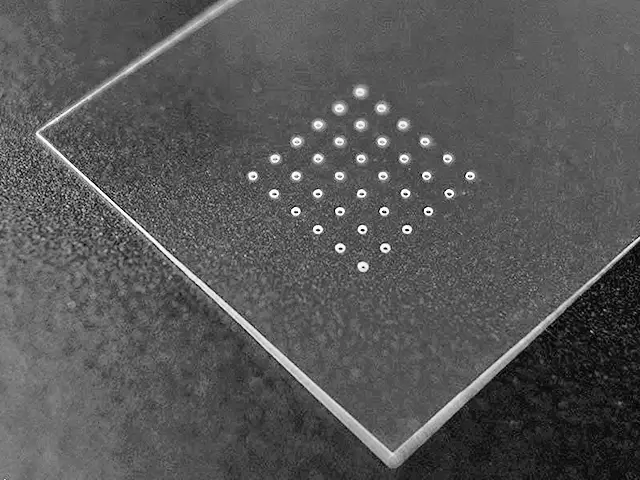

Helical Drilling

The laser beam moves in a helical or spiral pattern to gradually remove material, forming a hole with high precision. This method provides excellent control over the hole’s dimensions and surface quality.

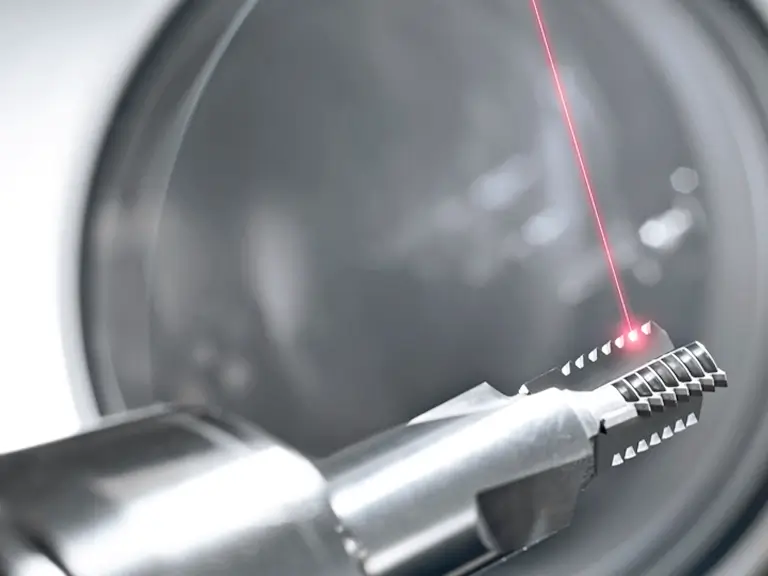

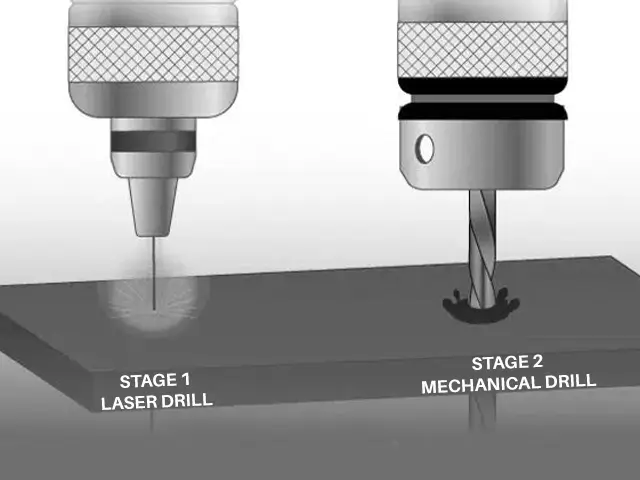

Hybrid laser drilling

It combines laser drilling with mechanical or waterjet processes to enhance precision and efficiency. It enables deeper holes, better material control, and improved surface quality, ideal for applications needing speed and accuracy in aerospace and manufacturing.

laser vs alternate

laser drilling

edm drilling

waterjet drilling