Laser marking technology

advantages of laser marking

Non-Contact Process

Laser ablation is used for precise material removal, cleaning, surface modification, and micromachining in various applications.

Minimal Material Waste

Laser ablation is used for precise material removal, cleaning, surface modification, and micromachining in various applications.

EXTREMELY Versatile

Laser ablation is used for precise material removal, cleaning, surface modification, and micromachining in various applications.

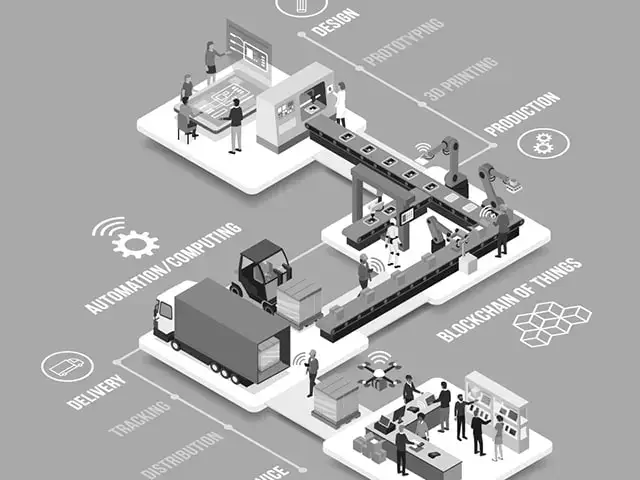

EASY INTEGRATION

Laser ablation is used for precise material removal, cleaning, surface modification, and micromachining in various applications.

types of laser marking

laser ABLATION

Laser ablation is used for precise material removal, cleaning, surface modification, and micromachining in various applications.

Laser Annealing

Laser annealing modifies the material’s surface structure to create smooth, high-contrast marks by inducing localized heating without material removal.

Laser Coloring

Laser coloring alters material surface properties, producing vibrant, permanent colors through oxidation or chemical changes for aesthetic and functional marks.

Laser Foaming

Laser foaming generates raised, high-contrast marks on plastics by inducing localized melting and gas bubble formation within the material’s surface.

Laser Engraving

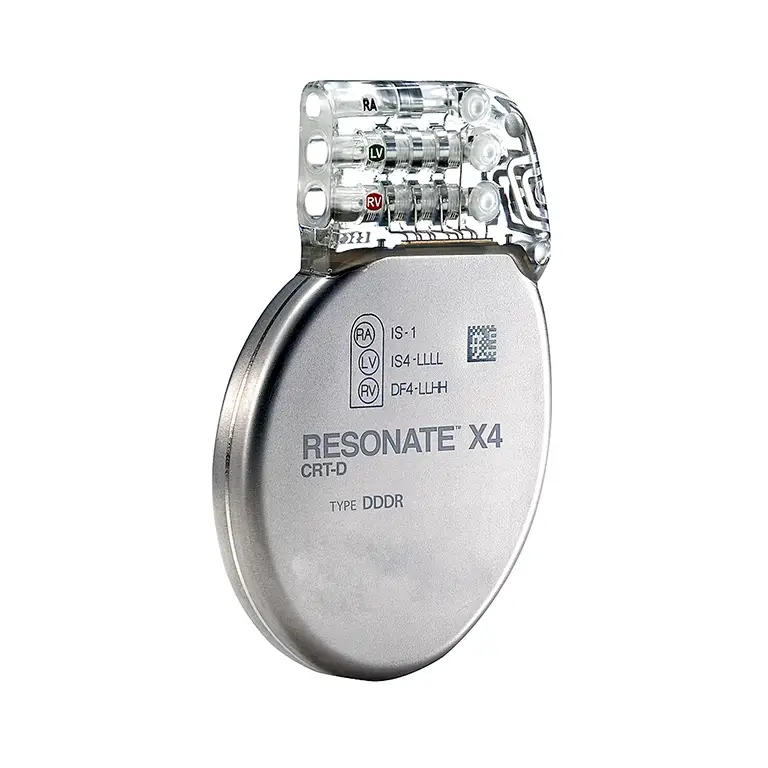

Laser engraving creates precise, permanent marks by removing material from the surface, achieving deep, durable, and detailed designs or text.

laser vs alternate

laser marking

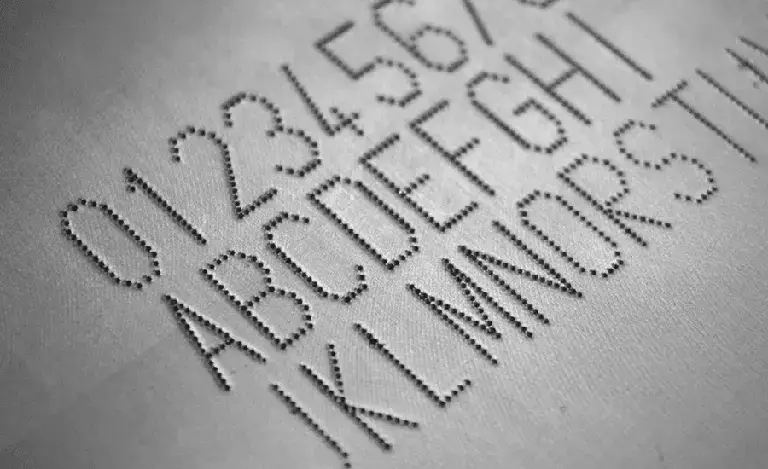

DOT PIN MARKING

INKJET PRINTING