advantages of robotic system

Precision and Consistency

Robots provide unmatched consistency and precision in laser applications, crucial for high-quality manufacturing standards.

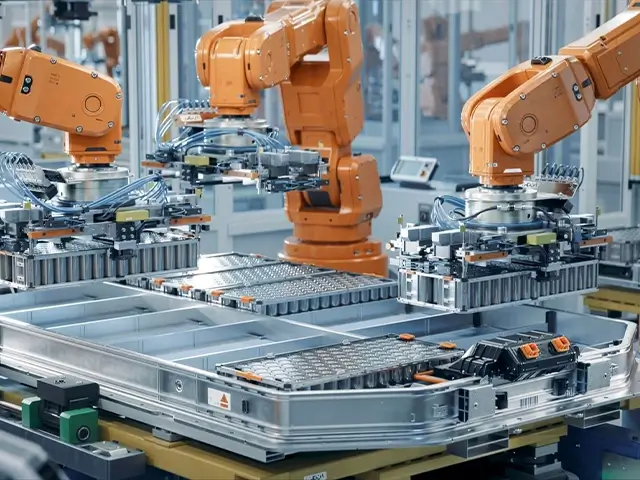

Flexibility and Adaptability

Robotic arms can reach difficult areas, handle various tasks, and adapt to different setups, making them highly versatile.

Increased Production Speed

Automation speeds up the production process, enabling higher throughput without sacrificing quality.

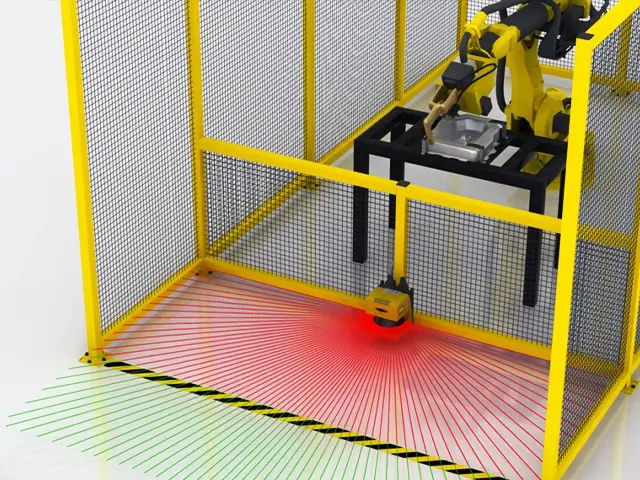

Enhanced Safety

Robots can operate in hazardous environments or handle dangerous tasks, reducing the risk to human operators.

Ideal laser processes for robotic system

laser cutting

Robotic laser cutting is ideal for high-precision cutting of metals, plastics, and other materials. Robots can handle complex paths and angles, offering excellent flexibility and speed. This is particularly useful in automotive, aerospace, and electronics manufacturing.

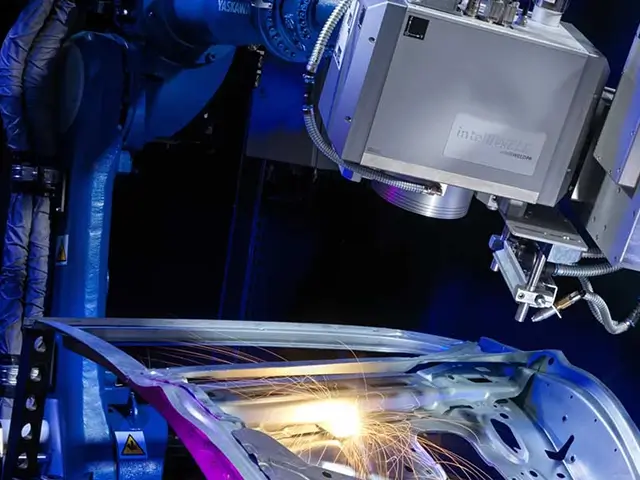

Laser welding

Robotic laser welding offers superior speed and precision compared to traditional welding methods. It’s especially useful for creating strong, precise welds in hard-to-reach areas or on small parts in industries like automotive and electronics. The process is highly repeatable and can be used with a variety of materials, including dissimilar metals.

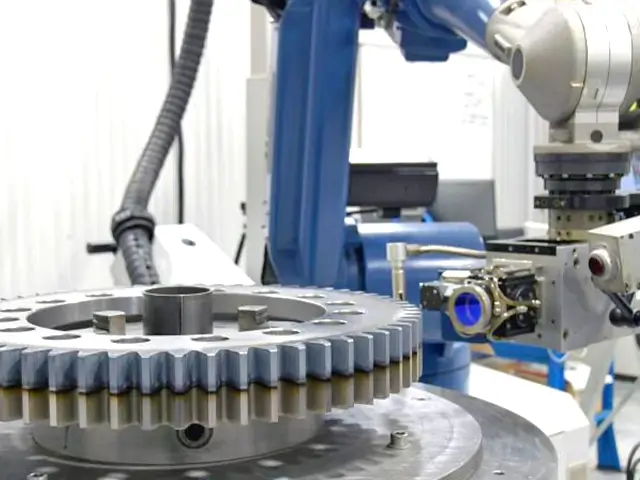

Laser hardening

Laser hardening is a precise and efficient method for improving the wear resistance and fatigue strength of metal parts without affecting the bulk properties of the material. When integrated with robotic systems, laser hardening offers enhanced control and automation, making it ideal for industrial applications where durability and precision are crucial.

Laser cladding

Laser cladding is an advanced laser process used for coating or rebuilding metal surfaces to enhance their wear, corrosion resistance, or mechanical properties. When integrated with robotic systems, laser cladding becomes an even more powerful tool for industries such as aerospace, automotive, oil and gas, and heavy machinery.