advantages of laser Applications in Pharma Industry

Non-Contact Process

Laser systems operate without direct contact with the product, reducing the risk of contamination and physical damage. This non-contact nature is particularly beneficial for maintaining the sterility and integrity of pharmaceutical products, ensuring they meet rigorous health and safety standards.

Precision and Accuracy

Lasers provide exceptional precision and accuracy, which are crucial in pharmaceutical manufacturing. They can produce intricate cuts and detailed markings on small, delicate products like tablets and capsules without damaging the product. This precision is essential for maintaining dosage integrity and ensuring consistent medication quality.

Traceability and Compliance

Lasers can engrave detailed, durable, and tamper-proof markings on pharmaceutical products and packaging. These markings, including serial numbers, expiration dates, and batch codes, enhance traceability and aid compliance with regulatory requirements like those outlined in the Drug Supply Chain Security Act (DSCSA) for tracking and tracing prescription medications.

Versatility

Laser technology is adaptable to various materials and surfaces, including hard tablets, capsules, soft gels, and various types of packaging materials. This versatility allows pharmaceutical companies to use a single laser system across different stages of production and for different products, reducing equipment costs and streamlining operations.

applications in pharma

- Pharmaceutical Systems

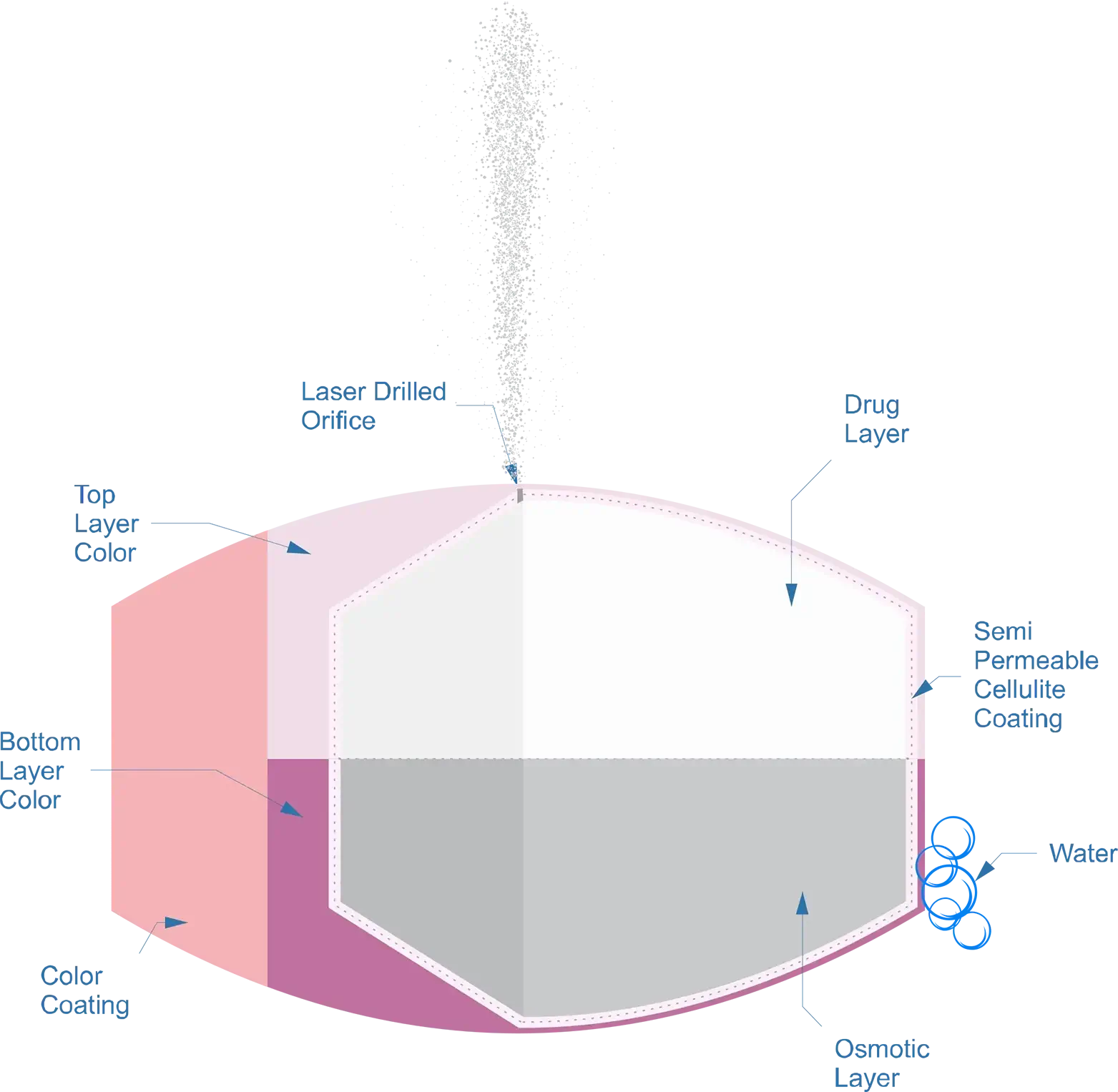

Tablet Laser Drilling

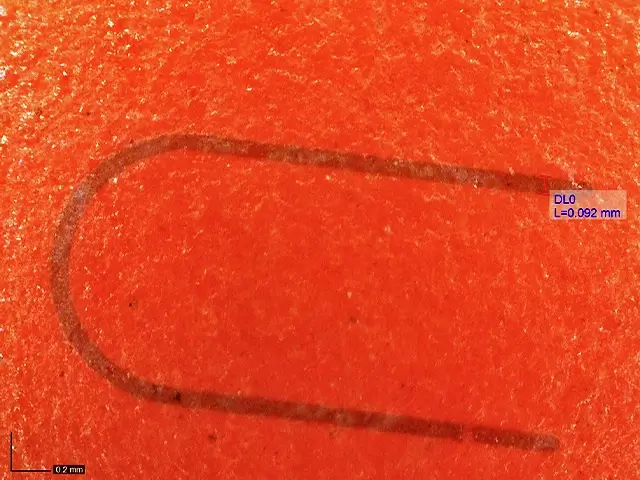

Tablet laser drilling is a sophisticated process technology used in the pharmaceutical industry to create controlled-release medication. This method involves using precise laser beams to drill one or more small holes in pharmaceutical tablets. These holes regulate the release of the drug’s active ingredients over time, which is crucial for medications that require consistent, gradual dosages to be effective.

The Tablet Drilling Laser System leverages advanced laser technology to provide precision-controlled drilling of pharmaceutical tablets. This system is designed to create micro-holes in the tablet coating, enabling modified or controlled release of active pharmaceutical ingredients. The technology uses high-precision lasers, typically CO₂ lasers, that can be finely tuned to adjust the diameter and depth of the holes based on specific drug release profiles.

- Systems

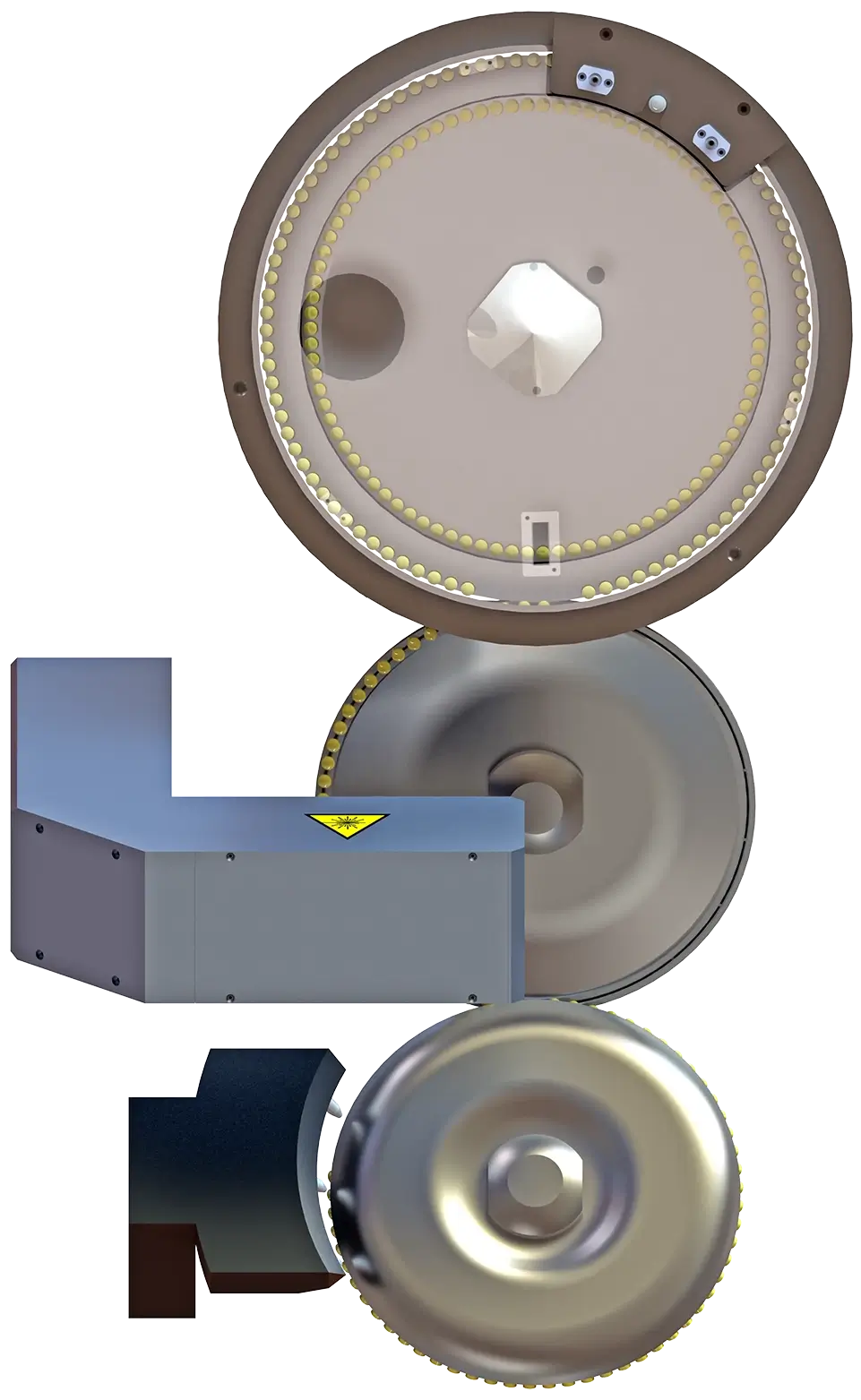

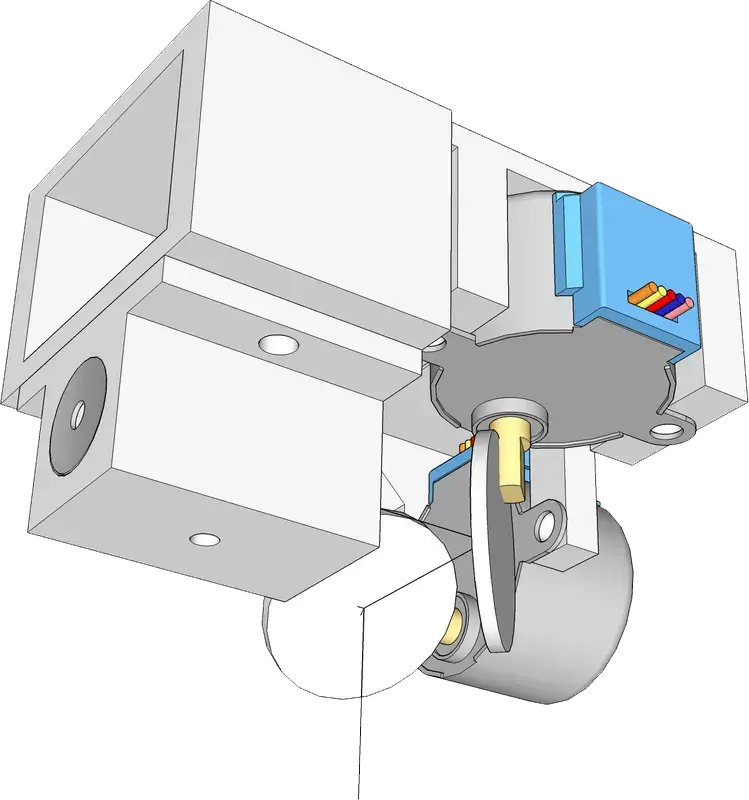

tablet laser drilling machine overview

Systems Overview

Our advanced Tablet Laser Drilling Machine System is engineered to meet the high demands of the pharmaceutical industry, offering precision drilling capabilities for osmotic pump time-release medications. Capable of processing up to 200,000 tablets per hour, the system can handle single or multiple drilling operations with orifice sizes ranging from 0.3mm to 1.5mm. Designed to work with mono-layer, bi-layer, bi-color round tablets, the system ensures each tablet undergoes a vision inspection. Additionally, it supports the integration of anti-counterfeit markings during the drilling process, enhancing security and compliance.

available Compliance

tablet laser drilling machine features

High-Speed Drilling

Achieves on-the-fly drilling of pharmaceutical tablets, maintaining high throughput without compromising precision.

Laser Configuration

Equipped with single or dual CO₂ laser options tailored to specific tablet types and drilling requirements.

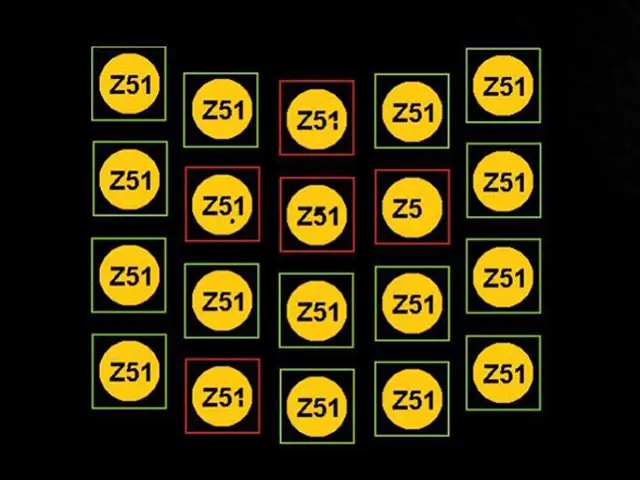

Vision Inspection

Camera system provides a comprehensive vision inspection to ensure quality and accuracy in every drilled tablet.

Feedback and Tracking

Implements true closed-loop feedback with on-the-fly tracking for real-time adjustments and quality control.

Superior Handling

Features an expertly designed bowl feeder and spindle system that facilitates smooth transitions between processes, reducing tablet breakage and enhancing overall yield.

User Interface and Software

Comes equipped with Scantech's iScada software on a Windows® 64-bit OS, providing an intuitive interface for system operation via a touchscreen display.

Construction and Safety

Constructed with a welded steel frame and FDA-approved stainless steel contact surfaces, ensuring durability. It includes a Class I laser workstation with emergency stop features and ergonomic controls for enhanced safety and usability.

Documentation and Compliance

Offers full support for Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) documentation. The system adheres to OSHA safety codes and exceeds GMP standards.

Documentation and Compliance

Offers full support for Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) documentation. The system adheres to OSHA safety codes and exceeds GMP standards.

tablet laser drilling machine models

ProLab Drill

The ProLab Drill Model is a compact, laboratory-grade tablet drilling system designed for research purposes. It efficiently handles setups of up to 100 tablets, offering a small footprint ideal for limited lab spaces.

ProMed

The ProMed Drill Model is optimized for smaller batch production, suitable for low-capacity manufacturing, handling up to 50,000 tablets per hour. This model is ideal for facilities requiring moderate production scales.

ProTab

The ProTab Drill Model excels in large batch production, designed for high-capacity manufacturing environments. It robustly produces up to 200,000 tablets per hour, making it ideal for extensive pharmaceutical operations.

- Pharmaceutical Systems

Tablet Laser Printing

The tablet laser printing machine employs advanced laser technology to imprint precise, high-resolution marks directly onto tablets. It offers a non-contact, ink-free method of printing that ensures durability and clarity of information such as batch numbers and expiration dates. Capable of handling high production volumes efficiently, this machine is pivotal for enhancing traceability and compliance in the pharmaceutical industry.

The tablet laser printing machine utilizes state-of-the-art laser technology to deliver precise, permanent markings on pharmaceutical tablets. Designed for high-speed operations, it ensures accurate printing without physical contact, minimizing damage and contamination. This machine supports a wide range of tablet sizes and shapes, making it versatile for various pharmaceutical applications, enhancing product safety and traceability.

- Systems

tablet laser printing machine overview

Systems Overview

Our sophisticated Tablet Printing Laser Machine System is meticulously engineered to meet the exacting demands of the pharmaceutical industry, offering high-precision, non-contact marking solutions. This system is capable of processing up to 200,000 tablets per hour, ensuring that each tablet, whether hard, softgel, or capsule, is accurately marked with essential data like expiration dates and batch numbers. Designed for impeccable quality control, the system includes comprehensive vision inspection capabilities that support Optical Character Recognition (OCR) and Optical Character Verification (OCV). Furthermore, it facilitates the integration of anti-counterfeit features, significantly enhancing product security and regulatory compliance. This makes it an indispensable tool for ensuring the traceability and authenticity of pharmaceutical products.

available Compliance

tablet laser printing machine features

These features collectively highlight the technological sophistication, safety considerations, regulatory compliance, and user-friendly design of the tablet laser printing machine, making it a valuable asset in modern pharmaceutical manufacturing environments.

High-Precision Marking

Utilizes advanced laser technology to print high-resolution, permanent markings on tablets, ensuring clarity and durability of information.

Non-Contact Printing Process

Offers a non-contact printing method that eliminates the risk of physical damage or contamination to the tablets during the marking process.

High Throughput Capacity

Capable of handling up to 150,000 tablets per hour, optimizing production efficiency and throughput for large-scale pharmaceutical operations.

Versatility

Supports a wide range of tablet types including hard tablets, softgels, and capsules, providing flexibility across different pharmaceutical product lines.

Advanced Vision Inspection

Incorporates comprehensive vision inspection systems that support Optical Character Recognition (OCR) and Optical Character Verification (OCV) to ensure accuracy and quality of each mark.

Anti-Counterfeit Features

Enables the implementation of advanced anti-counterfeit markings such as unique identifiers and secure QR codes to enhance product security and traceability.

Documentation & Compliance

Fully supports Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) documentation, ensuring compliance with industry standards such as GMP and FDA regulations.

Construction & Safety

Built with a robust steel frame and FDA-approved stainless steel contact surfaces, featuring a Class I laser safety enclosure and emergency stop mechanisms to ensure operational safety.

User Interface & Software

Equipped with an intuitive touch screen interface and state-of-the-art software that allows easy operation and monitoring of the system, enhancing user accessibility and control.

tablet laser printing machine models

ProLaB Print

The ProLab Print Model is a compact, laboratory-grade tablet printing system designed for research purposes. It efficiently handles setups of up to 100 tablets, offering a small footprint ideal for limited lab spaces.

ProPill

The ProPill Model is tailored for smaller batch production, suitable for facilities with low production capacity, efficiently printing up to 50,000 tablets per hour. This model offers a practical solution for moderate-scale pharmaceutical operations.

ProGel

The ProGel Model excels in high-capacity environments, specifically designed for printing on softgels. Capable of handling up to 200,000 tablets per hour, it is ideal for large-scale pharmaceutical manufacturing that demands efficiency and precision.

- Pharmaceutical Systems

vial or ampoule laser drilling & Printing

Our advanced laser systems offer specialized solutions for both drilling and printing on vials and ampoules. The drilling technology allows precise aperture creation for controlled substance release, while the printing system delivers high-resolution, durable markings for traceability and compliance, making them essential in pharmaceutical manufacturing.

Our state-of-the-art product technology integrates laser drilling and printing systems tailored for vials and ampoules. The drilling unit provides precise, controlled openings for dosage regulation, while the printing module ensures crisp, permanent markings for enhanced traceability and regulatory compliance, optimizing pharmaceutical packaging processes.

- Solutions Overview

Vial or Ampoule laser drilling & marking machine overview

System Overview

Our comprehensive vial laser drilling and marking systems are engineered to meet the stringent demands of the pharmaceutical industry. The laser drilling machine meticulously creates precise orifices in vial caps, optimizing controlled-release medication delivery. Simultaneously, our laser marking technology offers high-resolution, permanent labeling solutions for enhanced traceability and compliance. Equipped with advanced optics and fine-tuned laser parameters, these systems ensure accuracy and repeatability across high-volume productions. Both units are designed for seamless integration into existing production lines, featuring user-friendly interfaces and robust construction for continuous operation, making them indispensable tools for modern pharmaceutical manufacturing.

available Compliance

Vial or Ampoule laser drilling & marking machine models

ProDrill

The ProLab Drill Model specializes in drilling small vent holes with high precision. Designed for laboratory use, this compact system is ideal for creating meticulous perforations in various materials, ensuring precision in research and development settings.

ProPrint

The ProLab Print Model offers precise, high-resolution printing of level scales, logos, and other detailed markings. This compact, efficient system is perfect for laboratory environments where space is limited and accuracy is critical.

- Pharmaceutical Systems

Plastic container laser marking

Laser marking technology for plastic containers in the pharmaceutical and medical industries provides precise, permanent markings for traceability and compliance, utilizing non-contact methods to ensure integrity and sterility of the containers without compromising material strength.

Our laser marking product technology for plastic containers in the pharmaceutical and medical sectors ensures durable, high-contrast markings for QR codes, batch numbers, and expiration dates, enhancing traceability while maintaining container integrity and compliance.

- Solutions Overview

Plastic container laser marking machine overview

System Overview

Our laser marking machine for plastic containers is specifically engineered to meet the rigorous standards of the pharmaceutical and medical industries. It delivers precise, permanent markings essential for product identification, traceability, and regulatory compliance. Utilizing state-of-the-art laser technology, this machine ensures high-contrast markings on various types of plastic materials without compromising the container's integrity. Designed for high-volume production, the system features advanced optics and customizable laser parameters to adapt to different marking requirements. Its robust construction and user-friendly interface facilitate seamless integration into existing production lines, making it a vital component in modern pharmaceutical and medical manufacturing processes.

available Compliance

Plastic container laser marking machine models

ProMark 1060

The ProMark 1060 is a fiber laser online marking machine designed specifically for the pharmaceutical and medical industries. This model excels in delivering high-quality, precise markings directly on plastic containers as they move through the production line. Equipped with a robust fiber laser, the ProMark 1050 ensures durable, high-contrast markings for enhanced traceability and compliance. Its efficient online marking capability allows for seamless integration into existing conveyor systems, promoting continuous operation without disrupting workflow. Ideal for high-speed environments, the ProMark 1050 is a reliable choice for companies looking to enhance operational efficiency and product identification accuracy.

ProMark 1205

The ProMark 1205 is a UV laser online marking machine tailored for high-precision applications in the pharmaceutical and medical industries. This model uses ultraviolet laser technology to achieve fine, high-contrast markings on plastic containers, ideal for delicate and non-invasive marking requirements. The UV laser ensures minimal heat impact, preserving the integrity of the containers while providing permanent, legible markings crucial for compliance and traceability. Designed for integration into high-speed production lines, the ProMark 1205 offers continuous, efficient marking processes, making it an excellent solution for enhancing product safety and quality assurance in demanding environments.

ProMark 1311

The ProMark 1311 is a CO₂ laser online marking machine designed specifically for efficient and effective marking on plastic containers used in the pharmaceutical and medical sectors. Utilizing CO₂ laser technology, this model provides excellent adaptability to various plastic materials, delivering clear, permanent markings that include barcodes, expiration dates, and other critical traceability information. The ProMark 1311's online marking system allows for seamless integration into existing production lines, ensuring continuous high-speed marking without interrupting the manufacturing process. Its robust design and reliable performance make it an essential tool for industries requiring high standards of compliance and precision.

- Pharmaceutical Systems

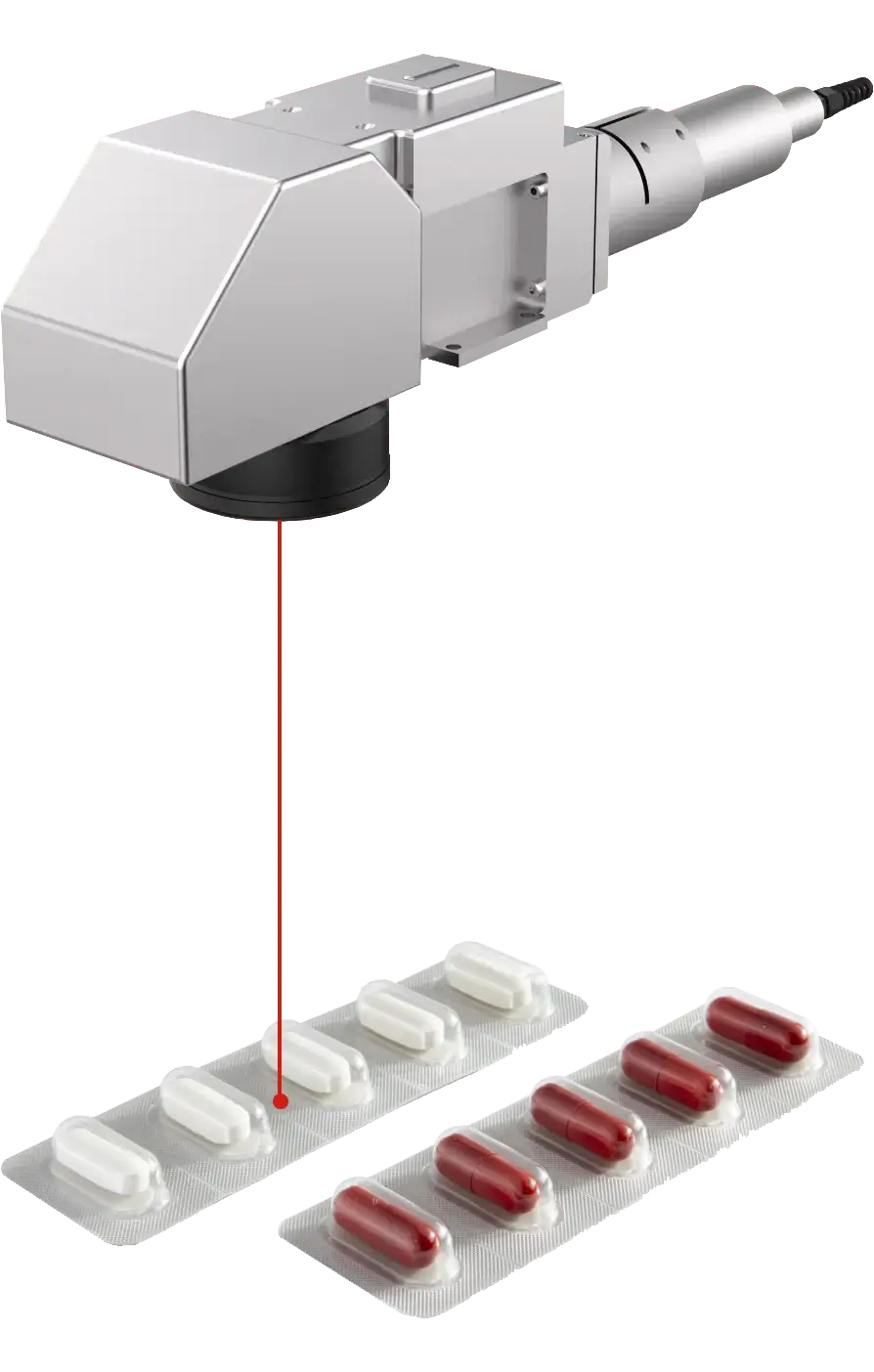

Blister Laser Batch coding

Blister Laser Batch Coding technology employs precise laser systems to etch batch codes directly onto blister packaging, ensuring permanent, tamper-proof markings for enhanced traceability, compliance with regulatory standards, and protection against counterfeiting in the pharmaceutical industry.

Blister Laser Batch Coding technology efficiently applies precise, permanent batch codes onto secondary packaging, such as blister packs and cartons. This method ensures clear, durable markings essential for traceability and compliance in pharmaceutical secondary packaging processes, suitable for high-throughput production environments.

- Solutions Overview

Blister Laser Batch coding machine overview

System Overview

Our Blister Laser Batch Coding Machine is specifically designed for the pharmaceutical industry to provide high-precision, non-contact coding on blister pack secondary packaging. Utilizing advanced laser technology, this machine ensures clear, permanent batch codes, expiry dates, and other critical tracking information are imprinted directly onto blister packs. Its high-speed operation is optimized for seamless integration into existing packaging lines, minimizing disruption and maximizing efficiency. The machine's robust design guarantees reliability and durability, even in high-volume production settings. Ideal for ensuring compliance with stringent regulatory standards, this system enhances product traceability and safety in pharmaceutical manufacturing.

available Compliance

Blister Laser Batch coding machine models

ProMark 1060

The ProMark 1060, a fiber laser online marking machine, is specifically designed to meet the demanding needs of the pharmaceutical and medical industries for blister batch coding. This model shines in its ability to deliver high-quality, precise markings directly onto blister packs as they move through the production line. Equipped with a robust fiber laser, the ProMark 1060 provides durable, high-contrast markings essential for accurate traceability and compliance. Its seamless integration into existing conveyor systems ensures continuous operation without disrupting workflow, making it highly suitable for high-speed production environments. The ProMark 1060 stands out as a reliable and efficient solution for enhancing blister pack identification and operational efficiency.

ProMark 1205

The ProMark 1205 UV laser online marking machine is expertly tailored for high-precision batch coding on blister packaging within the pharmaceutical and medical industries. This model employs advanced ultraviolet laser technology, renowned for its ability to produce fine, high-contrast markings essential for delicate applications. The UV laser ensures minimal thermal impact on sensitive blister materials, preserving the structural integrity while providing permanent, legible markings necessary for stringent compliance and traceability. Optimized for high-speed production environments, the ProMark 1205 integrates seamlessly into existing lines, enhancing operational efficiency and product safety with its continuous and non-invasive marking capabilities.

- Pharmaceutical Systems

Carton Laser Marking

Carton laser marking technology in the pharmaceutical packaging industry offers precise, permanent printing for traceability and compliance. It ensures high-contrast, smudge-proof markings for batch numbers, expiration dates, and barcodes, enhancing product safety and regulatory adherence.

Carton laser marking technology in the pharmaceutical industry uses advanced lasers to imprint high-resolution, durable markings on packaging. This ensures legible, tamper-proof information critical for tracking, compliance, and consumer safety, suitable for high-speed production lines.

- Systems

Carton Laser Marking machine overview

System Overview

Our Carton Laser Marking Machine is meticulously engineered to meet the critical demands of the pharmaceutical packaging industry. This system employs state-of-the-art laser technology to deliver high-resolution, permanent markings on cartons, essential for product traceability and regulatory compliance. It provides precise, non-contact marking that ensures legibility and durability of batch numbers, expiration dates, and barcodes without damaging the packaging material. Designed for high-volume production, the machine features advanced optics and adjustable laser parameters to accommodate various carton designs and sizes. Its robust construction and user-friendly interface allow for seamless integration into existing packaging lines, making it a vital tool for ensuring continuous, efficient operations in pharmaceutical manufacturing.

available Compliance

Carton Laser Marking machine models

ProMark 1311

The ProMark 1311, originally designed for marking on plastic containers, is equally effective for carton marking in the pharmaceutical and medical industries. This CO₂ laser online marking machine adapts seamlessly to different packaging materials, including paperboard cartons. It provides clear, permanent markings crucial for compliance and traceability—such as barcodes, expiration dates, and batch numbers—without compromising the integrity of the carton. With its ability to integrate smoothly into existing production lines, the ProMark 1311 ensures continuous, high-speed marking operations, enhancing productivity without disrupting the workflow. Its sturdy construction and consistent performance make it indispensable for maintaining high compliance standards and operational precision in carton marking.

ProMark 1315

The ProMark 1315 is an advanced CO₂ laser online marking machine, designed to deliver even faster and more powerful performance than the ProMark 1311. Tailored for use in the pharmaceutical and medical industries, it excels at marking both plastic containers and cartons with superior efficiency. The enhanced power of the ProMark 1315 ensures deeper, more prominent markings essential for barcodes, expiration dates, and batch numbers, all while maintaining the integrity of the packaging. Its high-speed marking capabilities integrate seamlessly into production lines, boosting throughput significantly without any production halts. Robust and reliable, the ProMark 1315 is a critical asset for industries demanding rigorous compliance and precision at higher operational tempos.

ProMark 1317

The ProMark 1317 represents the pinnacle of CO₂ laser online marking technology, offering the highest speed and power available in the series. This model is specifically engineered for the most demanding pharmaceutical and medical packaging tasks, where marking speed and clarity are paramount. Even faster and more powerful than the ProMark 1315, the ProMark 1317 effortlessly handles high-volume, high-speed marking requirements on a variety of packaging materials, including robust plastic containers and delicate cartons. Its integration into existing production lines is smooth and disruption-free, designed to handle continuous operation at peak performance levels. For enterprises targeting maximum efficiency and compliance, the ProMark 1317 is the ultimate marking solution, ensuring optimal traceability and product safety.