SCANTECH in CONSTRUCTION INDUSTRY

Scantech Laser is transforming the construction industry with state-of-the-art laser technology designed to enhance precision, efficiency, and quality in building processes. Our innovative solutions cater to a wide range of construction needs, from structural steel cutting and welding to detailed architectural engraving. By integrating advanced laser systems into construction workflows, Scantech Laser ensures that projects meet exacting standards with reduced timelines and increased cost-effectiveness.

CONSTRUCTION APPLICATIONS

OVERVIEW

Laser welding is increasingly being recognized as a transformative technology in the construction industry, offering enhanced precision, speed, and strength in joining various materials. This method is particularly valuable in environments where traditional welding could compromise component integrity or is impractical due to the complexity of the structures involved.

APPLICATIONS

Structural Steel Joining:

- Application: Laser welding is extensively utilized for joining structural steel components used in building frameworks, bridges, and large infrastructure projects. Its ability to produce strong, deep penetration welds ensures the durability and safety of the structures.

- Use Case: In the construction of high-rise buildings, laser welding facilitates the rapid assembly of steel beams and columns with reduced onsite labor requirements and enhanced joint integrity.

Prefabricated Construction Modules:

- Application: In prefabricated building modules, laser welding is used to assemble different components in a factory setting before they are transported to the construction site. This approach significantly speeds up construction time and improves build quality.

- Use Case: Modular homes and office buildings benefit from laser welding by ensuring that modules are constructed with precise, strong welds that contribute to the overall structural integrity once assembled on site.

Reinforcement Bar (Rebar) Welding:

- Application: Laser welding is applied to weld rebar in concrete constructions, providing enhanced load-bearing capacities and structural reinforcement.

- Use Case: In the construction of foundations and load-bearing walls, laser-welded rebar networks offer superior strength and durability, particularly in seismic zones.

Piping and HVAC Installations:

- Application: Laser welding is used for sealing and joining metal pipes and ducts in HVAC systems, ensuring leak-proof connections with minimal thermal distortion.

- Use Case: In large commercial buildings, laser-welded HVAC components are critical for ensuring efficient air distribution and system reliability.

Architectural Metalwork and Decorative Components:

- Application: Laser welding is ideal for attaching small or delicate metal components in architectural designs, allowing for intricate assemblies without damaging the aesthetics of the design.

- Use Case: For intricate metal facades and decorative staircases, laser welding provides strong joints that maintain the clean lines and visual integrity of the design.

Advantages of Laser Welding in Construction:

- Precision and Quality: Laser welding offers unmatched precision, reducing the need for post-weld finishing and ensuring that assemblies fit perfectly.

- Strength and Durability: Welds made by lasers are known for their depth and strength, which are essential for structural applications where safety is paramount.

- Speed of Execution: Laser welding is considerably faster than traditional welding, allowing for quicker project completion times.

- Reduced Material Wastage: The accuracy of laser welding means that material usage is optimized, reducing waste.

- Safety: Laser welding, being a non-contact process, enhances safety on construction sites by reducing the risks associated with manual welding.

Conclusion:

Laser welding is reshaping the construction industry by providing robust, efficient, and precise welding solutions. As the industry continues to seek innovative methods to improve safety, reduce costs, and accelerate construction timelines, laser welding stands out as a key technology driving these advancements. This technology not only supports current construction practices but also paves the way for future developments in building technology.

overview

Laser cutting technology is revolutionizing the construction industry by providing precise, efficient, and versatile cutting solutions for a wide range of materials. This advanced method enables clean, accurate cuts with minimal waste and reduced need for secondary processing, making it ideal for both structural and decorative applications in modern construction projects.

Key Applications and Use Cases:

APPLICATIONS

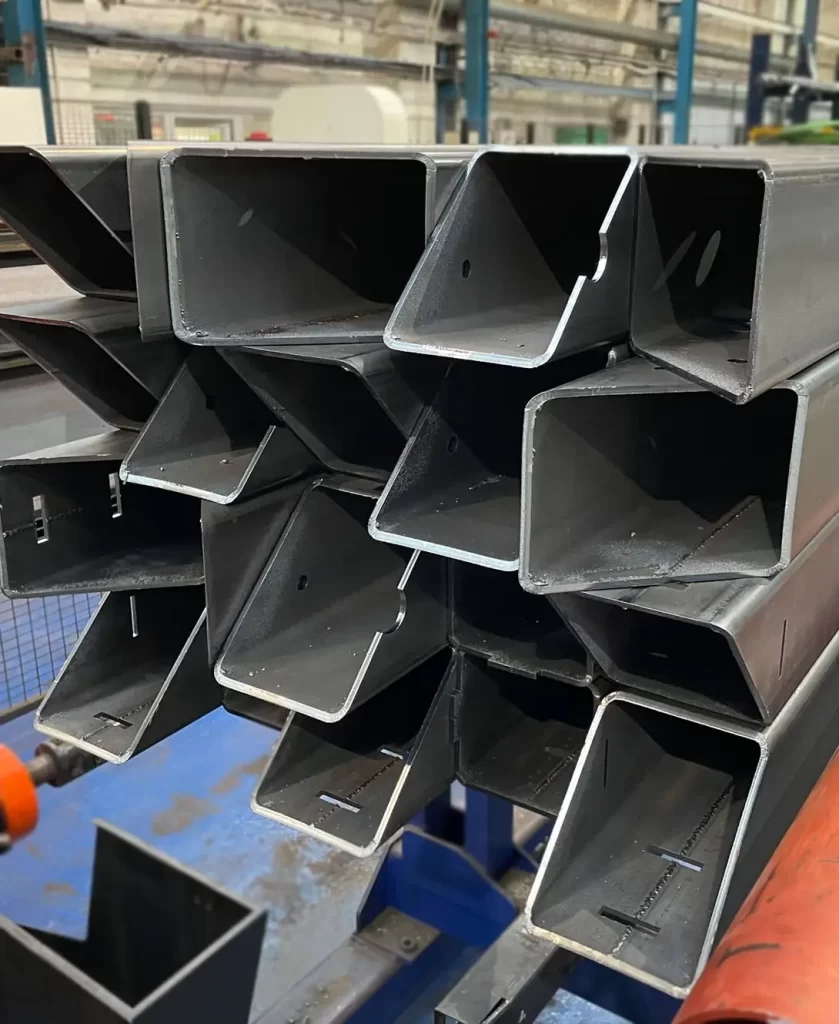

Cutting Structural Steel:

- Application: Laser cutting is extensively used for shaping structural steel elements, such as beams, girders, and plates, which are fundamental in creating the skeletal framework of buildings and other structures.

- Use Case: In the construction of skyscrapers and large commercial complexes, laser-cut steel components are preferred for their precision and the ability to fit together seamlessly, enhancing the overall speed and safety of the construction process.

Fabrication of Metal Facades and Architectural Details:

- Application: Laser cutting is ideal for creating complex, intricate designs required for metal facades, cladding, and decorative architectural elements.

- Use Case: For projects that feature unique architectural designs, such as customized metal panels or intricate lattice works, laser cutting provides the necessary precision and versatility to bring these complex designs to life.

HVAC Components:

- Application: In the HVAC industry, laser cutting is used to fabricate ductwork and other components with high accuracy and perfect fitting.

- Use Case: Accurate and efficient cutting of metal sheets for ductwork ensures that HVAC systems are leak-proof and optimized for energy efficiency, which is critical in large building projects.

Precise Cutting of Flooring Materials:

- Application: Laser cutting is used for precise shaping and sizing of various flooring materials, including intricate designs in tiles and stone.

- Use Case: For high-end residential and commercial buildings, laser-cut tiles and stone allow for exquisite floor designs that are aesthetically pleasing and perfectly aligned.

Window and Door Fabrication:

- Application: Lasers are used to cut metal for window frames and door systems, ensuring precise edges and corners for a perfect fit.

- Use Case: In both residential and commercial construction, laser-cut windows and doors ensure that frames match exact specifications for enhanced durability and aesthetics.

Advantages of Laser Cutting in Construction:

- High Precision and Quality: Laser cutting delivers exceptionally clean and precise cuts, reducing the need for additional finishing and fitting during construction.

- Speed and Efficiency: The speed of laser cutting significantly shortens production times compared to traditional cutting methods.

- Flexibility: Lasers can cut a wide variety of materials and thicknesses, from steel to composites, adapting easily to the diverse needs of construction projects.

- Reduced Waste: The accuracy of laser cutting minimizes material wastage, contributing to cost savings and environmental sustainability.

- Automation Compatibility: Laser cutting technology integrates well with CAD/CAM systems, allowing for automated and streamlined production processes.

Conclusion:

Laser cutting is a key technological advancement in the construction industry, supporting the development of more complex, efficient, and high-quality construction projects. Whether it’s through the fabrication of structural components or the creation of intricate architectural details, laser cutting enhances the capabilities of the construction sector, ensuring projects are not only visually impressive but also structurally sound and economically viable.

OVERVIEW

Laser marking technology is increasingly recognized as a crucial tool in the construction industry, providing a fast, reliable, and permanent method for marking various construction materials. This technique is used to add traceability, enhance safety, and improve quality control processes across a wide range of construction applications. With its ability to produce high-resolution marks without damaging the material, laser marking is ideal for both functional and aesthetic applications in construction projects.

APPLICATIONS

Material Traceability and Identification:

- Application: Laser marking is used to imprint serial numbers, part numbers, and barcodes directly on construction materials such as steel beams, pipes, and aluminum panels.

- Use Case: This ensures each piece of material can be traced throughout the supply chain, aiding in inventory management and ensuring that the correct materials are used at the correct stages of the construction process.

Safety Marking:

- Application: Safety instructions, warning signs, and other critical information are laser-marked onto machinery, tools, and safety equipment used on construction sites.

- Use Case: Laser marks are durable and resistant to the harsh environments found on construction sites, ensuring that safety communications are clearly visible and long-lasting.

Customization and Aesthetics:

- Application: Laser marking is utilized for customizing architectural elements like tiles, glass, and decorative panels with logos, designs, or text.

- Use Case: In premium residential or commercial buildings, customized laser markings add a unique aesthetic touch to the interiors or façades, enhancing the overall design and branding of the property.

Component Alignment and Assembly:

- Application: Precise alignment marks, assembly instructions, and position indicators are laser-marked directly onto components such as prefabricated building modules or mechanical systems.

- Use Case: These marks guide workers during the construction assembly process, reducing errors and speeding up the installation of complex components.

Regulatory Compliance:

- Application: Compliance codes, certification marks, and construction standards are permanently marked on building materials and components.

- Use Case: This ensures that all materials meet regulatory requirements and standards, facilitating inspections and compliance checks throughout the construction process.

Advantages of Laser Marking in Construction:

- Durability: Laser markings are highly resistant to physical wear, chemicals, and environmental factors, making them ideal for the rough conditions of construction sites.

- Precision: Laser technology allows for highly detailed and precise markings, which are essential for accuracy in custom applications and regulatory markings.

- Efficiency: Laser marking processes are fast and can be easily integrated into existing manufacturing lines, significantly reducing marking time compared to traditional methods.

- Non-Contact Process: Since laser marking does not require physical contact, it can be used on delicate materials without risk of damage or alteration to the material’s properties.

- Versatility: Lasers can mark a wide range of materials used in construction, including metals, plastics, glass, and more, making it a flexible tool for various marking needs.

Conclusion:

Laser marking technology is playing an increasingly vital role in modern construction practices. Its applications range from enhancing operational efficiency and ensuring material traceability to adding aesthetic value and ensuring compliance with safety standards. As construction projects become more complex and regulations more stringent, the role of laser marking is set to grow, providing essential solutions to meet the evolving demands of the industry.

OVERVIEW

Laser engraving is transforming the construction industry by offering a precise, efficient, and versatile method for engraving detailed designs, text, and graphics onto a variety of construction materials. This non-contact process minimizes damage and waste, making it an ideal solution for both functional and decorative purposes in modern construction environments.

APPLICATIONS

Architectural Detailing:

- Application: Laser engraving is used to create intricate patterns, images, and text on building facade materials such as stone, glass, and metal panels.

- Use Case: Enhancing building aesthetics with custom-engraved designs on facade panels or glass windows that not only serve as architectural highlights but also convey branding or historical information.

Signage and Wayfinding:

- Application: Durable signage for both interiors and exteriors is created using laser engraving, which can etch detailed graphics and text into wood, metal, or acrylic.

- Use Case: Production of clear, long-lasting signs that guide visitors through large complexes like hospitals, universities, and corporate campuses, ensuring durability and visibility in various weather conditions.

Marking for Installation and Assembly:

- Application: Laser engraving provides precise markings for the alignment, installation, and assembly of building components such as panels, flooring, and structural supports.

- Use Case: Engraved labels and instructions on construction materials help streamline the assembly process, reducing errors and speeding up construction timelines.

Custom Interior Decorations:

- Application: Detailed engravings on interior surfaces such as wooden fixtures, stone countertops, and ceramic tiles.

- Use Case: Personalization of residential or commercial spaces with unique, bespoke decorative elements that elevate interior design schemes.

Safety Markings:

- Application: Engraving safety warnings and emergency information directly onto structural elements or machinery used on construction sites.

- Use Case: Permanent, wear-resistant markings ensure that safety and operational guidelines are always visible and clear, enhancing on-site safety compliance.

Tool and Equipment Identification:

- Application: Engraving identification numbers, logos, or QR codes on construction tools and equipment.

- Use Case: Helps manage inventory, reduce theft, and facilitate easy identification and tracking of tools and equipment across large job sites.

Advantages of Laser Engraving in Construction:

- Precision and Clarity: Laser engraving offers unmatched detail and accuracy, ideal for producing precise graphics and text.

- Durability: Engravings are resistant to fading, wear, and environmental damage, crucial for construction applications where long-term durability is essential.

- Efficiency: The process is quick and can be automated, allowing for high-volume production without compromising quality.

- Flexibility: Capable of engraving a wide range of materials, laser engraving is suitable for numerous applications across different phases of construction.

- Reduced Waste: As a non-contact process, laser engraving minimizes material waste and damage during operation, contributing to more sustainable construction practices.

Conclusion:

Laser engraving stands as a pivotal technology in the construction industry, enhancing both the functionality and aesthetics of modern construction projects. Its ability to deliver detailed and durable engravings makes it indispensable for adding intricate designs, improving navigation, enhancing safety, and much more. As the construction industry continues to innovate, the role of laser engraving is set to expand, providing essential solutions that meet the evolving demands of this dynamic field.

OVERVIEW

Laser cleaning is an innovative and environmentally friendly technology increasingly adopted in the construction industry for its precision and efficacy in removing contaminants, coatings, and debris from various surfaces without damaging the substrate. This non-contact cleaning method uses laser light to vaporize surface-level impurities, providing a clean finish that is ideal for preparation, restoration, and maintenance tasks in construction environments.

APPLICATIONS

Surface Preparation for Painting and Coating:

- Application: Laser cleaning is used to prepare metal, stone, and concrete surfaces by removing rust, scale, old paint, or other contaminants before repainting or applying new coatings.

- Use Case: Ensuring that bridge structures, steel frameworks, and building facades are thoroughly cleaned to achieve better adhesion and longevity of the new coatings, enhancing structural durability and aesthetic appearance.

Restoration of Historical Buildings:

- Application: In the restoration of historical structures, laser cleaning delicately removes accumulated pollution, biological growth, and previous restoration materials from stone, brick, and wood surfaces without harming the original material.

- Use Case: Preserving architectural details and integrity while revitalizing the appearance of historical buildings, monuments, and statues.

Removal of Graffiti and Vandalism:

- Application: Quickly and effectively removing graffiti from concrete walls, stone monuments, and metal surfaces using laser technology.

- Use Case: Restoring public spaces, buildings, and transport infrastructure to their original condition, maintaining the environment’s visual appeal and cleanliness.

Cleaning of Concrete and Stone Surfaces:

- Application: Laser cleaning efficiently removes dirt, mildew, and algae from concrete and stone surfaces, improving their appearance and preventing material degradation.

- Use Case: Enhancing the curb appeal and extending the life of concrete and stone elements in urban and residential construction.

Mold and Lead Paint Removal:

- Application: Safely removing mold and hazardous materials like lead-based paints from interior and exterior surfaces.

- Use Case: Ensuring the safety and health compliance in renovation projects, especially in older buildings where these hazardous materials are prevalent.

Advantages of Laser Cleaning in Construction:

- Precision Cleaning: Lasers offer controlled and localized cleaning, ensuring that only the unwanted materials are removed while preserving the underlying substrate.

- Environmentally Friendly: Unlike traditional methods that often require harsh chemicals or abrasive techniques, laser cleaning is an eco-friendly process that leaves no secondary waste or contaminants.

- Efficiency and Speed: Laser cleaning processes are rapid and can be significantly more efficient than manual cleaning methods, saving time and labor costs on large projects.

- Safety and Non-Contact: The non-contact nature of laser cleaning reduces physical stress on workers and eliminates the need for physical scraping or chemical exposure.

- Versatility: Capable of cleaning a wide range of materials and contaminants, making it suitable for diverse applications across the construction sector.

Conclusion:

Laser cleaning technology is reshaping maintenance and restoration practices within the construction industry. Its ability to provide precise, efficient, and environmentally friendly cleaning solutions makes it an invaluable tool for modern construction projects, from large-scale structural applications to delicate historical preservation. As the industry continues to focus on sustainable and efficient practices, laser cleaning is poised to become a standard method for ensuring clean, well-maintained, and visually appealing structures.

DEDICATED TO INNOVATION

Scantech is dedicated to advancing the construction industry by providing specialized material and application expertise tailored to meet the unique demands of our clients. Equipped with advanced laser technology and supported by decades of experience, we focus on helping construction professionals navigate current industry challenges such as cost efficiency, structural integrity, and resource sustainability. Our goal is to optimize construction processes through precision laser solutions that enhance building safety, efficiency, and architectural versatility, fostering innovation in the creation of durable, cost-effective, and environmentally friendly structures.

Elevating Construction with Precision Technology

Advancing Construction with Innovative Laser Solutions

Our approach to the construction industry allows us to envision its long-term future while addressing the immediate needs for growth and development. Whether it’s optimizing structural components through advanced laser cutting techniques, enhancing building integrity with precise laser welding, or improving material traceability with durable laser marking, Scantech Laser’s solutions are at the forefront of construction innovation. These technologies not only increase the efficiency and safety of construction projects but also ensure that every element conforms to the highest standards of quality and durability.

Driving the Future of Automotive Manufacturing

As the construction industry continues to evolve, Scantech Laser remains committed to supporting its growth with innovative, reliable, and efficient laser solutions. We are dedicated to understanding the industry’s unique challenges and providing the technologies that will drive its success in the years to come. Together, we’re not just meeting the needs of today; we’re propelling the construction industry into the future, ensuring that our solutions help build safer, more efficient, and sustainable structures.