SCANTECH IN PHOTOVOLTAIC

The photovoltaic (PV) industry relies heavily on laser technology to enhance the efficiency and production quality of solar panels. Lasers are instrumental in several critical steps during the manufacturing of photovoltaic cells and modules. They offer precision, non-contact processing that reduces material waste and damage, improving the overall performance of solar panels. Laser applications in this sector focus on increasing the conductivity and energy efficiency of photovoltaic cells while streamlining production processes.

PHOTOVOLTAIC APPLICATIONS

overview

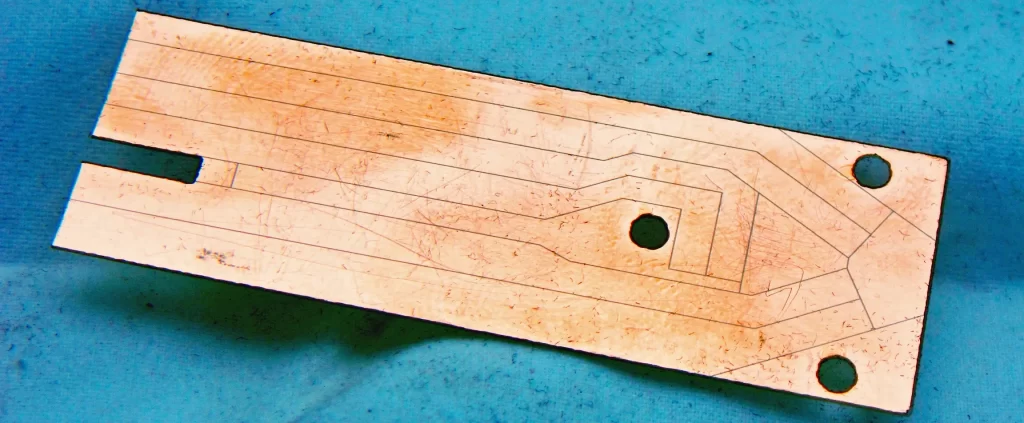

Laser cutting technology is crucial in the photovoltaic (PV) industry, where precision, efficiency, and material optimization are key to producing high-performance solar cells and modules. Laser cutting is used to process various components of photovoltaic systems, including silicon wafers, glass, and other delicate materials. The non-contact nature of laser cutting ensures minimal damage to sensitive materials, while its precision allows for intricate designs and efficient material usage. This technology is instrumental in enhancing the efficiency, reliability, and cost-effectiveness of solar energy products.

APPLICATIONS

Silicon Wafer Dicing:

- Application: Laser cutting is used to dice silicon wafers into individual solar cells. The precision of laser cutting ensures clean, narrow kerf widths, which reduces material loss and maximizes the number of cells that can be produced from each wafer.

- Benefit: Enhances material utilization and reduces waste, leading to lower production costs and higher efficiency in solar cell manufacturing.

Glass and Encapsulant Cutting:

- Application: Laser cutting is used to cut glass substrates and encapsulant materials that protect solar cells within a module. The precision of laser cutting ensures that these materials are cut to exact dimensions, facilitating seamless assembly and reducing material waste.

- Benefit: Provides clean, precise cuts that are essential for maintaining the integrity and durability of solar modules, while also improving manufacturing efficiency.

Busbar and Grid Finger Cutting:

- Application: Laser cutting is utilized to precisely cut busbars and grid fingers on solar cells. These are the conductive paths that collect and transfer electricity generated by the solar cell. Precise cutting ensures optimal electrical performance and reduces resistance losses.

- Benefit: Enhances the electrical efficiency of solar cells, contributing to higher overall module efficiency.

Cutting of Back Sheets and Insulating Layers:

- Application: Laser cutting is used to process back sheets and insulating layers in solar modules. These layers protect the active components of the solar cells from environmental damage and electrical hazards.

- Benefit: Ensures that protective layers are cut accurately, maintaining the safety and longevity of the solar modules.

Advantages of Laser Cutting in the Photovoltaic Industry:

- High Precision and Accuracy: Laser cutting offers unparalleled precision, crucial for the intricate designs and tight tolerances required in photovoltaic manufacturing.

- Minimal Material Waste: The ability to create narrow kerf widths and precise cuts reduces material waste, lowering production costs and increasing the efficiency of solar cell production.

- Non-Contact Process: The non-contact nature of laser cutting eliminates the risk of mechanical damage to sensitive materials, ensuring high-quality results.

- Speed and Efficiency: Laser cutting is a fast process, enabling high-throughput production lines that can meet the growing demand for solar energy products.

- Versatility: Laser cutting can be applied to a wide range of materials used in photovoltaic manufacturing, including silicon, glass, polymers, and thin films, making it a versatile tool for various stages of production.

Solutions Offered by Scantech Laser:

- High-Power Laser Cutting Systems: Our laser cutting systems are designed for high-precision cutting of silicon wafers, thin films, and other photovoltaic materials, ensuring optimal performance and efficiency in solar cell and module production.

- Automated Laser Cutting Solutions: We provide fully automated laser cutting systems that integrate with existing production lines, enhancing throughput and consistency while reducing labor costs.

- Custom Laser Solutions: Scantech offers tailored laser cutting solutions to meet specific requirements in the photovoltaic industry, whether for specialized materials, unique geometries, or high-volume production needs.

Conclusion:

Laser cutting is an essential technology in the photovoltaic industry, enabling the precise and efficient processing of materials that are critical to the performance and reliability of solar cells and modules. Scantech Laser’s advanced cutting solutions empower manufacturers to produce high-quality, high-efficiency photovoltaic products, helping to drive the adoption of solar energy worldwide.

OVERVIEW

Laser marking is a critical technology in the photovoltaic (PV) industry, offering precise, permanent, and high-contrast markings on various components of solar panels and cells. These markings are essential for product traceability, quality control, branding, and compliance with industry regulations. Laser marking is non-contact, highly accurate, and adaptable to a wide range of materials, making it an ideal solution for the PV industry where durability and precision are paramount.

APPLICATIONS

Serial Number and Batch Code Marking:

- Application: Laser marking is used to engrave serial numbers, batch codes, and other unique identifiers on solar cells and modules. These markings are crucial for traceability throughout the manufacturing process and the product’s lifecycle.

- Benefit: Ensures that each solar cell and module can be tracked and traced from production to installation, facilitating quality control and compliance with industry standards.

Branding and Logo Marking:

- Application: Solar panel manufacturers use laser marking to add company logos, product names, and other branding elements to their products. This helps in differentiating their products in a competitive market.

- Benefit: Provides clear, durable branding that remains visible throughout the product’s life, enhancing brand recognition and consumer trust.

QR Code and Data Matrix Marking:

- Application: Laser marking is employed to engrave QR codes, Data Matrix codes, and other machine-readable identifiers on solar panels and components. These codes are used for automated tracking, inventory management, and quick access to product information.

- Benefit: Enables efficient tracking and management of solar products throughout the supply chain, improving inventory accuracy and reducing operational costs.

Performance and Specification Marking:

- Application: Laser marking is used to inscribe performance data, such as power output, efficiency ratings, and voltage details, directly onto solar cells or modules. This information is crucial for installers and users to understand the capabilities of the product.

- Benefit: Provides permanent, legible markings that ensure installers and users have access to critical performance information, helping to optimize the installation and use of solar panels.

Safety and Compliance Marking:

- Application: Laser marking is used to apply safety warnings, certification marks, and compliance information required by regulatory bodies. This is essential for ensuring that solar products meet legal requirements and safety standards.

- Benefit: Ensures that solar products are compliant with international safety and regulatory standards, reducing the risk of legal issues and enhancing product safety.

Advantages of Laser Marking in the Photovoltaic Industry:

- High Precision and Clarity: Laser marking provides sharp, high-contrast marks that are easy to read, even on small surfaces like solar cells.

- Durability: The marks created by laser are resistant to environmental factors such as UV light, weathering, and abrasion, ensuring that they remain legible throughout the product’s lifespan.

- Non-Contact Process: Laser marking is a non-contact method, meaning there is no risk of damaging delicate components during the marking process.

- Flexibility: Laser marking can be used on a wide variety of materials commonly found in the PV industry, including silicon, glass, polymers, and metals.

- Speed and Efficiency: Laser marking is a fast process that can be easily integrated into automated production lines, allowing for high-throughput marking with consistent quality.

Solutions Offered by Scantech Laser:

- High-Precision Fiber Laser Marking Systems: Designed for marking on a wide range of photovoltaic materials, our fiber laser systems deliver clear, permanent marks that are essential for traceability and compliance.

- CO2 Laser Marking Solutions: Ideal for marking non-metallic materials such as glass and polymers used in solar modules, our CO2 lasers offer flexibility and high-quality results.

- Automated Laser Marking Systems: Scantech provides fully automated laser marking systems that integrate seamlessly into existing production lines, ensuring high-speed, consistent marking across large volumes of solar products.

- Custom Laser Marking Solutions: We offer tailored laser marking solutions to meet the specific needs of the photovoltaic industry, whether for unique material combinations, specialized marking requirements, or high-volume production.

Conclusion:

Laser marking is an indispensable technology in the photovoltaic industry, offering precise, durable, and efficient solutions for marking and labeling solar cells, modules, and components. These markings play a critical role in ensuring traceability, compliance, and brand visibility, all of which are essential for the success and reliability of solar energy products. Scantech Laser’s advanced marking solutions empower manufacturers to meet the highest standards of quality and performance, driving the growth and adoption of solar energy worldwide.

OVERVIEW

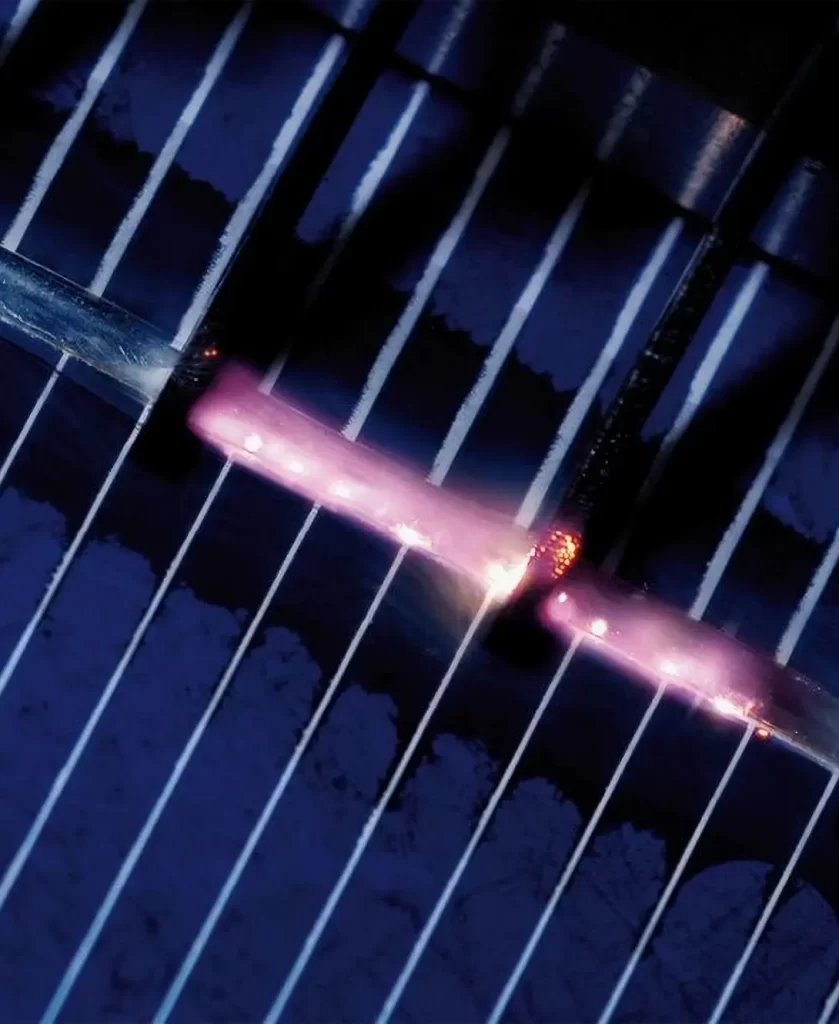

Laser scribing is a critical process in the photovoltaic (PV) industry, particularly in the manufacturing of thin-film solar cells and modules. This precise, non-contact method involves using a laser to create fine lines or grooves on the surface of photovoltaic materials, enabling the electrical isolation of individual cells and the creation of electrical connections within a solar module. Laser scribing is essential for enhancing the efficiency and performance of solar cells, allowing manufacturers to produce high-quality, high-efficiency photovoltaic products.

APPLICATIONS

Thin-Film Solar Cell Structuring:

- Application: Laser scribing is used to structure thin-film solar cells by creating precise scribe lines that divide the film into individual cells. These scribe lines separate the different layers of the thin-film material (such as TCO, semiconductor, and back contact layers) and are crucial for defining the electrical paths within the module.

- Benefit: Ensures high efficiency and optimal performance of thin-film solar cells by precisely controlling the electrical isolation and connection of individual cells.

P1, P2, and P3 Scribing:

- Application: In thin-film PV manufacturing, laser scribing is categorized into three main types: P1, P2, and P3. P1 scribing creates the initial isolation scribe on the transparent conductive oxide (TCO) layer. P2 scribing is used to remove the semiconductor layer, creating an interconnect, while P3 scribing isolates the back contact layer. These steps are essential for defining and connecting the active areas of the solar cells.

- Benefit: Provides precise and controlled scribing at each stage, ensuring the proper functioning of the thin-film solar cells and reducing electrical losses.

CIGS and CdTe Solar Modules:

- Application: Laser scribing is used extensively in the production of Copper Indium Gallium Selenide (CIGS) and Cadmium Telluride (CdTe) thin-film solar modules. The laser creates fine, uniform lines that help in forming the electrical connections between cells and improving overall module efficiency.

- Benefit: Enhances the performance and reliability of CIGS and CdTe modules by ensuring that the scribing process is precise and consistent across the entire module.

Micromachining for Flexible Solar Cells:

- Application: For flexible solar cells, laser scribing is used to create highly precise and intricate patterns that accommodate the flexible nature of the substrate. This allows the cells to maintain their electrical integrity while being bent or rolled.

- Benefit: Enables the production of lightweight, flexible solar panels that can be used in a wide range of applications, from portable electronics to building-integrated photovoltaics (BIPV).

Enhanced Efficiency through Reduced Dead Zones:

- Application: Laser scribing reduces the size of dead zones (areas where no electricity is generated) by creating narrow scribe lines that minimize material loss. This is particularly important in maximizing the active area of each solar cell.

- Benefit: Increases the overall efficiency of the solar module by maximizing the area available for energy generation.

Advantages of Laser Scribing in the Photovoltaic Industry:

- High Precision and Control: Laser scribing provides exceptional precision, allowing for the creation of narrow, clean lines that are essential for the electrical isolation and interconnection of cells within a module.

- Non-Contact Process: The non-contact nature of laser scribing eliminates the risk of mechanical damage to delicate thin-film materials, ensuring the integrity of the solar cells.

- Increased Module Efficiency: By minimizing dead zones and optimizing the electrical paths, laser scribing contributes to higher overall efficiency of photovoltaic modules.

- Versatility: Laser scribing can be applied to various types of thin-film materials, including CIGS, CdTe, and amorphous silicon, making it a versatile solution for different PV technologies.

- Automation Compatibility: Laser scribing systems can be easily integrated into automated production lines, enhancing throughput and ensuring consistent quality in large-scale manufacturing.

Solutions Offered by Scantech Laser:

- High-Precision Laser Scribing Systems: Our systems are designed to deliver the precise, controlled scribing required for thin-film PV manufacturing, ensuring optimal performance of solar cells and modules.

- Multi-Stage Laser Scribing Solutions: Scantech offers systems that can perform P1, P2, and P3 scribing in a single setup, streamlining the production process and improving efficiency.

- Custom Laser Scribing Solutions: We provide tailored solutions to meet the specific needs of photovoltaic manufacturers, including specialized scribing patterns, materials, and production volumes.

- Automated Laser Scribing Systems: Our automated solutions integrate seamlessly with existing production lines, enabling high-speed, consistent scribing across large volumes of thin-film solar modules.

Conclusion:

Laser scribing is a vital technology in the photovoltaic industry, enabling the precise structuring and electrical connection of thin-film solar cells. This process is essential for producing high-efficiency, reliable solar modules that meet the growing demand for renewable energy. Scantech Laser’s advanced scribing solutions empower manufacturers to optimize their production processes, improve product quality, and drive the adoption of solar energy on a global scale.

OVERVIEW

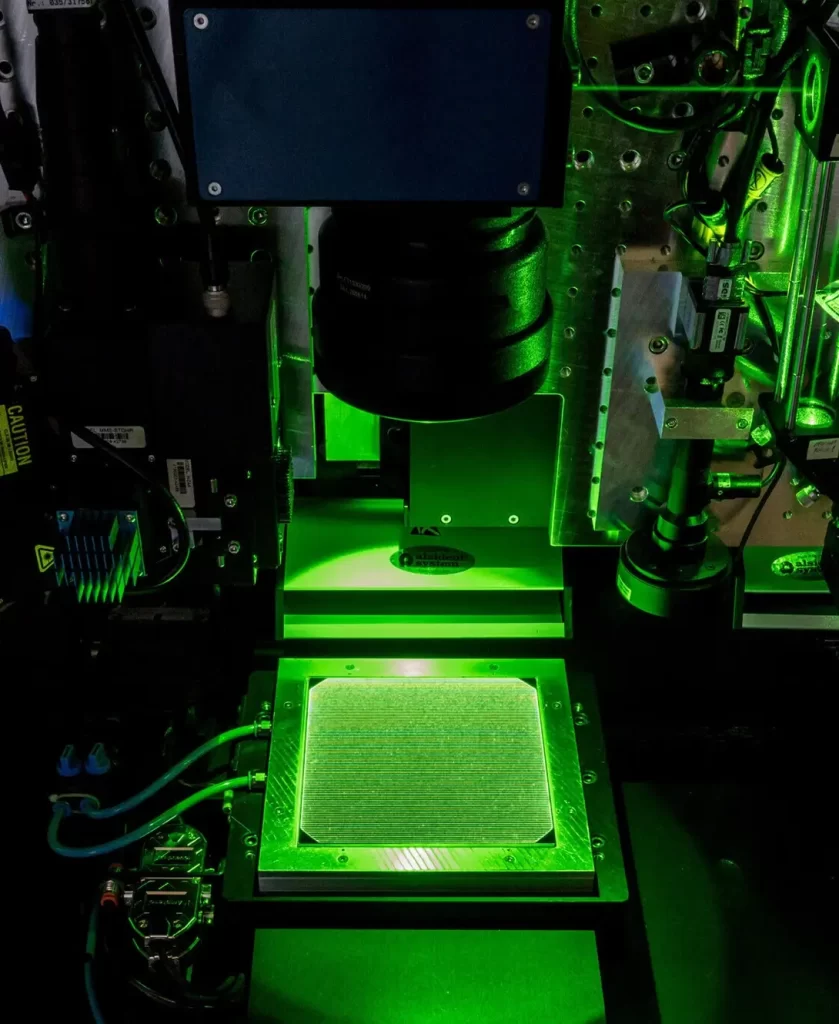

Laser drilling is a crucial technology in the photovoltaic (PV) industry, offering precision and efficiency in the fabrication of solar cells and modules. This non-contact process uses focused laser energy to create precise, micro-scale holes in various photovoltaic materials, such as silicon wafers and thin-film layers. Laser drilling is instrumental in enhancing the performance, reliability, and efficiency of solar cells by enabling advanced designs and improving electrical connections. It is particularly valuable in applications where traditional mechanical drilling methods may cause damage or are impractical.

APPLICATIONS

Via Hole Drilling in Silicon Solar Cells:

- Application: Laser drilling is used to create via holes in silicon solar cells for the formation of electrical contacts on the rear side of the cell. These holes allow for the connection of conductive layers, enhancing the overall efficiency of the solar cell by reducing front-side shading and improving electrical performance.

- Benefit: Enables the production of high-efficiency solar cells, such as Passivated Emitter Rear Contact (PERC) cells, by providing a method to connect rear-side contacts without compromising the cell’s active surface area.

Hole Drilling for Metal Wrap-Through (MWT) Technology:

- Application: In Metal Wrap-Through (MWT) solar cells, laser drilling is used to create holes that allow the front-side metal contacts to be wrapped through to the rear side of the cell. This reduces shading on the front surface and increases the active area of the solar cell.

- Benefit: Improves the efficiency of solar cells by increasing the light absorption area, leading to higher power output from the same cell area.

Drilling for Interconnection in Thin-Film Solar Cells:

- Application: Laser drilling is applied in the interconnection of thin-film solar cells, where precise holes are needed to connect different layers or modules. This is particularly important in the manufacturing of flexible or multi-junction solar cells.

- Benefit: Ensures reliable electrical connections between layers, which is crucial for the performance and durability of thin-film photovoltaic modules.

Back Contact Solar Cell Drilling:

- Application: Laser drilling is used to create small, precise holes in back-contact solar cells, allowing for the connection of electrodes on the rear side of the cell. This design reduces shading on the front surface and enhances the cell’s efficiency.

- Benefit: Supports the production of high-efficiency back-contact solar cells, which are increasingly popular in advanced photovoltaic applications.

Texturing and Light Trapping Enhancement:

- Application: Laser drilling can be used to create micro-scale textures on the surface of solar cells, enhancing light trapping and increasing the absorption of sunlight. This is particularly effective in improving the efficiency of both crystalline silicon and thin-film solar cells.

- Benefit: Increases the overall energy conversion efficiency of solar cells by maximizing the amount of light absorbed and converted into electricity.

Advantages of Laser Drilling in the Photovoltaic Industry:

- High Precision and Accuracy: Laser drilling provides the precision needed to create micro-scale holes and features that are essential for advanced solar cell designs.

- Minimal Thermal Impact: The focused nature of the laser minimizes heat-affected zones, reducing the risk of damage to surrounding materials and maintaining the integrity of delicate photovoltaic structures.

- Non-Contact Process: Laser drilling does not involve physical contact with the material, eliminating mechanical stress and reducing the likelihood of material deformation or damage.

- Versatility: Laser drilling can be applied to a wide range of photovoltaic materials, including silicon wafers, thin films, and emerging materials, making it a versatile solution for various PV technologies.

- Enhanced Production Efficiency: Laser drilling is a fast, automated process that can be easily integrated into production lines, increasing throughput and reducing manufacturing costs.

Solutions Offered by Scantech Laser:

- High-Precision Laser Drilling Systems: Our laser drilling systems are designed for the precise creation of micro-holes in photovoltaic materials, ensuring optimal performance in advanced solar cell designs.

- Automated Laser Drilling Solutions: Scantech offers automated laser drilling solutions that integrate seamlessly with existing production lines, providing consistent, high-quality results at high speeds.

- Custom Laser Drilling Solutions: We provide tailored laser drilling solutions to meet the specific needs of photovoltaic manufacturers, whether for specialized materials, unique geometries, or high-volume production requirements.

- Multi-Functional Laser Systems: Scantech’s multi-functional laser systems can perform drilling, cutting, and marking operations in a single setup, streamlining production processes and improving overall efficiency.

Conclusion:

Laser drilling is a vital technology in the photovoltaic industry, enabling the production of advanced, high-efficiency solar cells and modules. By providing precise, non-contact drilling solutions, laser technology enhances the performance, reliability, and cost-effectiveness of photovoltaic products. Scantech Laser’s advanced drilling solutions empower manufacturers to optimize their production processes, improve product quality, and drive the adoption of solar energy on a global scale.

OVERVIEW

Laser edge isolation is a critical process in the photovoltaic (PV) industry, particularly in the manufacturing of crystalline silicon solar cells. This process involves using a laser to precisely remove the unwanted conductive layer from the edges of the solar cell, preventing electrical short circuits between the front and rear surfaces. Edge isolation is essential for improving the efficiency and reliability of solar cells by ensuring that the electrical current is directed correctly through the cell. Laser technology provides a non-contact, highly precise method for edge isolation, offering superior results compared to traditional chemical or mechanical methods.

APPLICATIONS

Crystalline Silicon Solar Cells:

- Application: Laser edge isolation is primarily used in the production of crystalline silicon solar cells, where it isolates the conductive front surface from the rear side to prevent short circuits. This is achieved by removing a narrow strip of the conductive emitter layer along the cell’s perimeter.

- Benefit: Enhances the electrical performance of the solar cells by ensuring proper current flow, thereby increasing the overall efficiency of the photovoltaic module.

High-Efficiency Cell Technologies (PERC, PERT, PERL):

- Application: Advanced cell technologies like Passivated Emitter Rear Contact (PERC), Passivated Emitter Rear Totally Diffused (PERT), and Passivated Emitter Rear Locally Diffused (PERL) cells benefit significantly from laser edge isolation. The process helps in achieving the high efficiencies these technologies are known for by precisely defining the active area of the cell.

- Benefit: Supports the production of high-efficiency solar cells by ensuring accurate and clean isolation of the cell’s edges, crucial for maximizing light absorption and minimizing recombination losses.

Reducing Recombination Losses:

- Application: By using laser edge isolation, manufacturers can reduce recombination losses that occur at the edges of the solar cells. This is particularly important for high-performance solar cells where every aspect of the cell design is optimized for maximum efficiency.

- Benefit: Increases the energy conversion efficiency of solar cells by reducing electrical losses and improving the cell’s power output.

Enhanced Module Reliability:

- Application: Laser edge isolation improves the reliability of solar modules by ensuring that the solar cells are free from potential short circuits. This reliability is crucial for long-term performance and warranty considerations in the photovoltaic industry.

- Benefit: Enhances the durability and long-term reliability of solar modules, reducing the risk of performance degradation over time.

Integration with Other Laser Processes:

- Application: Laser edge isolation can be integrated with other laser processes, such as laser doping and laser annealing, to streamline the manufacturing process and enhance the overall efficiency of the solar cells.

- Benefit: Provides a more efficient production process by combining multiple laser operations in a single setup, reducing manufacturing time and costs.

Advantages of Laser Edge Isolation in the Photovoltaic Industry:

- High Precision and Control: Laser edge isolation offers unmatched precision, allowing for the removal of the emitter layer without damaging the underlying silicon material.

- Non-Contact Process: The non-contact nature of laser processing ensures that the solar cells are not subjected to mechanical stress, reducing the risk of cracking or other damage.

- Increased Efficiency: By preventing electrical short circuits and reducing recombination losses, laser edge isolation directly contributes to higher solar cell efficiencies.

- Environmentally Friendly: Unlike chemical edge isolation methods, laser edge isolation does not require hazardous chemicals, making it a more environmentally sustainable option.

- Automation Compatibility: Laser edge isolation systems can be easily integrated into automated production lines, ensuring consistent quality and high throughput.

Solutions Offered by Scantech Laser:

- Precision Laser Edge Isolation Systems: Our systems are designed to deliver precise and consistent edge isolation for crystalline silicon solar cells, ensuring optimal electrical performance.

- Automated Laser Edge Isolation: Scantech offers fully automated laser edge isolation systems that integrate seamlessly with existing production lines, providing high-speed processing and consistent results.

- Custom Laser Solutions: We provide tailored laser edge isolation solutions to meet the specific needs of photovoltaic manufacturers, including specialized material handling, integration with other processes, and high-volume production capabilities.

- Multi-Function Laser Systems: Scantech’s multi-function laser systems can perform edge isolation along with other processes like scribing and drilling, streamlining production and improving efficiency.

Conclusion:

Laser edge isolation is a vital process in the photovoltaic industry, directly impacting the efficiency and reliability of solar cells. By providing precise, non-contact edge isolation, laser technology helps manufacturers produce high-performance, high-reliability solar cells that meet the growing demands of the renewable energy market. Scantech Laser’s advanced edge isolation solutions enable manufacturers to enhance the quality and efficiency of their photovoltaic products, driving the global adoption of solar energy.

DEDICATED TO INNOVATION

At Scantech Laser, our commitment to the photovoltaic industry goes beyond merely addressing customer needs; it’s about pioneering innovation and shaping the future of renewable energy. Aware of the critical role that the photovoltaic sector plays in the global transition to sustainable energy, we are dedicated to delivering customized laser solutions that meet the unique challenges and opportunities within this industry. Whether it’s improving the efficiency of solar cells through precision laser scribing, enhancing production speeds, or reducing material waste, our focus is on driving the advancement of photovoltaic technology with cutting-edge laser innovations.

Advancing Photovoltaic Manufacturing with Laser Technology

In the rapidly evolving photovoltaic industry, precision, speed, and reliability are crucial. Scantech Laser’s state-of-the-art laser technologies are expertly designed to meet these demands, offering solutions that significantly boost the efficiency and quality of solar panel production processes. From laser scribing and cutting to marking and structuring, our advanced systems deliver unmatched precision and consistency. This ensures that every photovoltaic component produced meets the highest standards of quality, driving forward the production of highly efficient solar panels.

Powering Photovoltaic Advancements with Laser Solutions

Our approach to the photovoltaic industry allows us to envision its long-term future while focusing on current growth and development needs. Whether it’s enhancing solar cell efficiency through advanced laser scribing techniques, improving panel durability with precise laser welding, or ensuring component traceability with durable laser marking, Scantech Laser’s solutions are at the forefront of photovoltaic innovation.

Powering the Future of Photovoltaics with Laser Solutions

As the photovoltaic industry continues to evolve, Scantech Laser remains committed to supporting its growth with innovative, reliable, and efficient laser solutions. We are dedicated to understanding the unique challenges of this industry and providing the technologies that will drive its success in the years to come. Together, we’re not just meeting the needs of today; we’re propelling the photovoltaic industry into the future.