Scantech in textile & leather

The textile and leather industries have increasingly incorporated laser technology to enhance production efficiency, improve design capabilities, and minimize waste. Lasers offer precision cutting, engraving, and marking solutions that are both efficient and eco-friendly compared to traditional mechanical methods. This technology is particularly beneficial in these industries for its ability to handle delicate materials, produce intricate designs, and operate at high speeds without direct contact, thus preventing material damage.

TEXTILE & LEATHER APPLICATIONS

overview

Laser cutting has revolutionized the textile and leather industries by offering a precise, efficient, and versatile method for cutting and shaping a wide range of materials. The ability to create intricate designs, clean edges, and complex patterns without causing damage to delicate fabrics or leather has made laser cutting an essential tool in modern fashion, upholstery, and accessory production. This technology enhances productivity, reduces material waste, and allows for greater creativity in design, making it a valuable asset in these industries.

APPLICATIONS

Precision Cutting of Fabrics:

- Application: Laser cutting is used to precisely cut fabrics for clothing, home textiles, and industrial applications. It is particularly effective for detailed patterns, complex shapes, and small production runs.

- Solution: Lasers provide clean cuts with sealed edges that prevent fraying, making them ideal for delicate materials such as silk, lace, and synthetic fabrics. This precision reduces the need for additional finishing processes, streamlining production.

Leather Cutting for Fashion and Accessories:

- Application: Laser cutting is widely used to cut leather for fashion items like shoes, belts, bags, and decorative elements. It is also used in the automotive and furniture industries for leather upholstery.

- Solution: The non-contact nature of laser cutting ensures that the leather is not distorted or damaged during the cutting process. Lasers can create intricate designs and patterns that would be difficult or time-consuming to achieve with traditional cutting methods, allowing for greater design flexibility.

Customization and Personalization:

- Application: Customizing and personalizing textile and leather products with unique designs, logos, or patterns for fashion, promotional items, and luxury goods.

- Solution: Laser cutting allows for precise and repeatable customization of products, enabling brands to offer personalized items at scale. This capability is particularly valuable in the growing market for bespoke and limited-edition products.

Perforation and Engraving:

- Application: Creating perforated designs in leather and textiles for aesthetic purposes, ventilation, or functional elements such as speaker grilles and decorative overlays.

- Solution: Lasers can produce small, precise holes or engravings without damaging the material, offering endless possibilities for creative design. This application is popular in fashion, automotive interiors, and high-end accessories.

Pattern Prototyping and Small Batch Production:

- Application: Quickly prototyping new designs and producing small batches of products, which is crucial for testing and developing new collections in fashion and accessories.

- Solution: Laser cutting allows designers to quickly create prototypes with exact specifications, enabling rapid iterations and adjustments. This agility helps reduce the time to market for new products and collections.

Advantages of Laser Cutting in the Textile & Leather Industry:

- Precision and Detail: Laser cutting provides high accuracy and the ability to cut complex shapes and intricate details that are difficult to achieve with traditional methods.

- Speed and Efficiency: The fast processing speed of laser cutting increases productivity, making it ideal for both large-scale production and small custom orders.

- Material Versatility: Lasers can cut a wide range of materials, including natural and synthetic textiles, leather, and composites, offering flexibility across different applications.

- Reduced Material Waste: The precision of laser cutting minimizes waste, leading to cost savings and more sustainable production practices.

- Non-Contact Processing: The non-contact nature of laser cutting prevents material deformation and damage, preserving the quality of the final product.

Conclusion:

Laser cutting has become an indispensable tool in the textile and leather industries, offering unmatched precision, efficiency, and versatility. Whether used for creating intricate patterns, customizing products, or enhancing production efficiency, laser cutting enables manufacturers to meet the demands of modern consumers with high-quality, innovative designs. As these industries continue to evolve, laser cutting will remain at the forefront, driving new possibilities in fashion, accessories, and upholstery production.

OVERVIEW

Laser engraving has become a powerful tool in the textile and leather industries, offering precise and detailed customization options for a wide range of products. This technology allows manufacturers to create intricate designs, logos, textures, and patterns on fabrics and leather with exceptional accuracy and consistency. Laser engraving is highly valued for its ability to personalize products, enhance aesthetics, and add value to textiles and leather goods, all while maintaining the integrity of the material.

APPLICATIONS

Personalization and Customization:

- Application: Engraving personalized messages, names, logos, or monograms on leather products such as wallets, belts, bags, and shoes, as well as on textile items like garments, hats, and home decor.

- Solution: Laser engraving allows for precise and permanent customization, making it ideal for creating unique, one-of-a-kind products that cater to individual customer preferences. This capability is especially popular in the fashion and luxury goods markets, where personalized items are in high demand.

Creating Intricate Patterns and Designs:

- Application: Engraving complex patterns, detailed artwork, or decorative elements onto leather and textile products to enhance their visual appeal.

- Solution: Laser engraving enables designers to create highly detailed and intricate patterns that would be challenging or impossible to achieve with traditional methods. This is particularly useful for fashion designers, interior decorators, and accessory makers looking to add a distinctive touch to their products.

Texturizing Leather and Fabrics:

- Application: Engraving textures onto leather and fabrics to create a unique look and feel, such as simulating embossing or adding a tactile surface to products like handbags, shoes, and jackets.

- Solution: Lasers can be used to create various textures on the surface of leather and textiles, providing a cost-effective way to achieve the appearance of embossed or textured materials without the need for additional tools or processes. This adds value and sophistication to products, making them more appealing to consumers.

Branding and Labeling:

- Application: Engraving brand logos, product information, care instructions, and other important details directly onto textile and leather products.

- Solution: Laser engraving provides a durable and high-contrast mark that is resistant to wear and tear, ensuring that branding and labeling remain legible throughout the product’s lifespan. This is essential for maintaining brand identity and ensuring compliance with labeling regulations.

Engraving for Prototyping and Small-Batch Production:

- Application: Quickly producing prototypes or small batches of engraved textile and leather products for testing new designs or limited-edition runs.

- Solution: Laser engraving allows for rapid prototyping and short production runs, enabling designers and manufacturers to experiment with new ideas and bring them to market quickly. This flexibility is key for responding to market trends and consumer demands.

Advantages of Laser Engraving in the Textile & Leather Industry:

- High Precision and Detail: Laser engraving offers the ability to create intricate designs and detailed patterns with exceptional accuracy, enhancing the quality and appearance of products.

- Consistency and Repeatability: Lasers provide consistent results across large production runs, ensuring that every piece meets the same high standards.

- Non-Contact Processing: The non-contact nature of laser engraving prevents material distortion and damage, preserving the quality of delicate fabrics and leathers.

- Customization Flexibility: Laser engraving can be easily adjusted to create a wide range of designs, making it ideal for personalized and custom products.

- Durability: Laser-engraved marks are permanent and resistant to fading, wear, and environmental factors, ensuring long-lasting quality.

Conclusion:

Laser engraving is a transformative technology in the textile and leather industries, offering unmatched precision, versatility, and aesthetic enhancement. Whether used for personalization, branding, or creating intricate designs, laser engraving allows manufacturers to elevate the quality and appeal of their products. As consumer demand for unique, customized, and high-quality goods continues to grow, laser engraving will play an increasingly important role in the future of textile and leather manufacturing.

OVERVIEW

Laser marking is a precise and permanent method for adding logos, serial numbers, care instructions, and other important information directly onto textiles and leather products. This non-contact process ensures that the material remains undamaged while providing high-contrast, durable markings that can withstand wear and environmental factors.

APPLICATIONS

Branding and Logos:

- Application: Marking brand logos on leather goods like bags, belts, and shoes, as well as on textiles such as apparel and accessories.

- Solution: Laser marking allows for the creation of detailed and permanent logos that enhance brand visibility and product differentiation. The marks are resistant to fading and wear, maintaining brand integrity over time.

Care Instructions and Labels:

- Application: Engraving care labels and product information directly onto textiles and leather, eliminating the need for additional tags.

- Solution: Laser marking ensures that care instructions remain legible throughout the product’s life, even after repeated washing or use. This approach is particularly useful for high-end products where aesthetic appeal and durability are key.

Security Marking:

- Application: Adding unique identification codes or anti-counterfeiting marks to valuable leather goods and textiles.

- Solution: Laser marking provides a tamper-proof solution that helps protect against counterfeiting, ensuring the authenticity of luxury items and providing traceability throughout the supply chain.

OVERVIEW

Laser perforation involves creating small, precise holes in textiles and leather materials. This process is used for both aesthetic and functional purposes, such as enhancing breathability in fabrics, creating decorative patterns, or enabling easy tearing of materials.

APPLICATIONS

Ventilation and Breathability:

- Application: Perforating sportswear fabrics, footwear, and leather goods to improve airflow and comfort.

- Solution: Laser perforation creates uniform holes that allow for better ventilation without compromising the material’s strength. This is ideal for athletic wear and shoes, where breathability is crucial for performance and comfort.

Aesthetic Design:

- Application: Adding decorative patterns to textiles and leather for fashion and accessory products.

- Solution: Laser perforation enables the creation of intricate designs that add a unique visual appeal to products. This technique is often used in high-end fashion to differentiate products and add a touch of luxury.

Functional Perforation:

- Application: Creating tear lines or foldable sections in packaging materials or leather products.

- Solution: Lasers can be used to create perforations that allow for easy tearing or folding, enhancing the functionality of packaging and making products more user-friendly.

OVERVIEW

Laser etching is a surface modification technique that creates detailed designs, textures, or patterns on textiles and leather. This process alters the material’s surface without removing any material, resulting in a subtle but visually striking effect.

APPLICATIONS

Texturizing and Surface Design:

- Application: Etching unique textures and patterns onto leather products such as handbags, shoes, and jackets, as well as textiles like denim and upholstery fabrics.

- Solution: Laser etching adds depth and character to materials, creating a distinctive look and feel. This technique is particularly popular in fashion and interior design for its ability to enhance the aesthetic value of products.

Custom Design and Personalization:

- Application: Etching personalized designs, names, or logos onto leather and textile products for a custom, bespoke finish.

- Solution: Laser etching allows for highly detailed and intricate designs that can be customized to individual preferences, making it ideal for luxury and bespoke items.

Brand Enhancement:

- Application: Adding subtle branding elements, such as logos or patterns, to products without overpowering the design.

- Solution: Laser etching provides a sophisticated way to incorporate branding into products, enhancing brand identity while maintaining a refined and elegant appearance.

OVERVIEW

Laser edge isolation is a technique used to create a clear boundary around the edges of textiles and leather materials, preventing fraying and maintaining the material’s integrity. This process is particularly useful in applications where clean, durable edges are essential.

APPLICATIONS

Fray Prevention:

- Application: Sealing the edges of textiles and leather to prevent fraying and unraveling, particularly in high-stress areas such as seams, hems, and cutouts.

- Solution: Laser edge isolation creates a clean, sealed edge that resists fraying, ensuring the longevity and durability of the material. This is especially important for products that undergo frequent use or washing.

Clean Cutting for Leather Goods:

- Application: Creating sharp, clean edges on leather products such as belts, straps, and accessories.

- Solution: Lasers provide precise edge isolation that enhances the overall quality and appearance of leather goods. This technique is essential for maintaining the aesthetic appeal and structural integrity of high-end leather products.

Enhanced Durability:

- Application: Reinforcing the edges of textiles used in upholstery, automotive interiors, and other applications where durability is key.

- Solution: Laser edge isolation ensures that the material withstands wear and tear, extending the life of the product and maintaining its appearance over time.

Conclusion:

Laser technology offers a wide range of applications and solutions in the textile and leather industries, from marking and perforation to etching and edge isolation. These processes not only enhance the functionality and durability of materials but also provide creative opportunities for design and customization. As the demand for high-quality, innovative products continues to grow, laser solutions will play an increasingly important role in the textile and leather industries, driving advancements in both aesthetics and performance.

DEDICATED TO INNOVATION

At Scantech Laser, our dedication to the textile and leather industry transcends merely meeting customer needs; it’s about pioneering innovation and shaping the future of these dynamic sectors. Acknowledging the critical role that textile and leather industries play in global fashion and manufacturing, we are committed to providing tailored laser solutions that address the unique challenges and opportunities these industries face. Whether it’s enhancing precision in cutting and engraving, reducing material waste, or enabling intricate design capabilities, our focus is on driving the evolution of textile and leather production with cutting-edge laser technology.

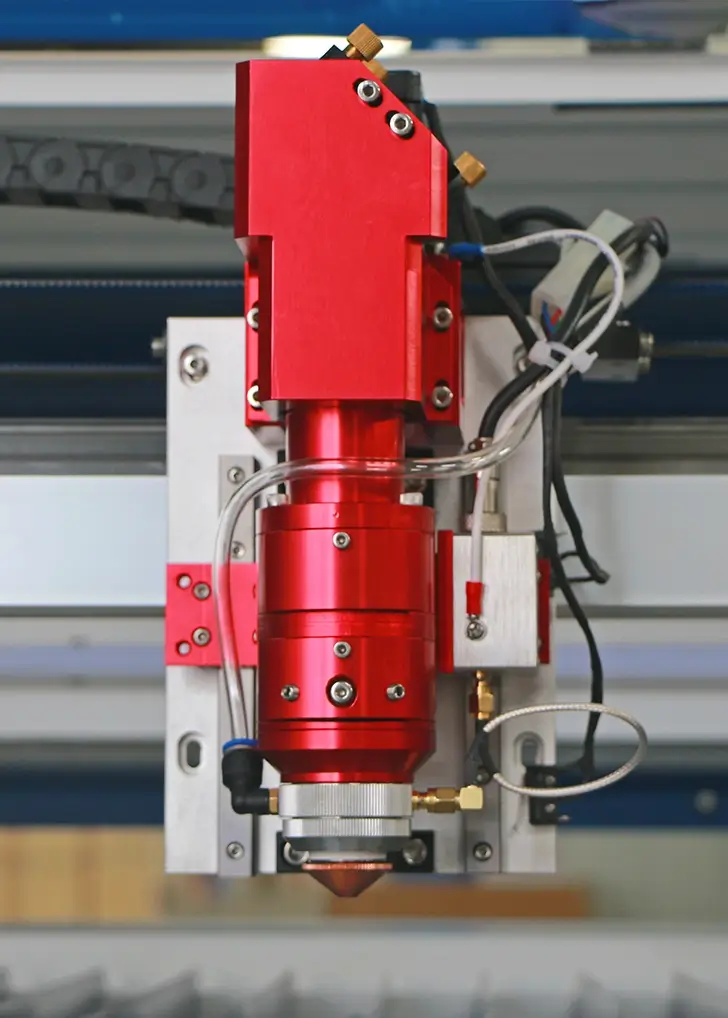

revolutionizing Textile & Leather Production with Laser Technology

In the dynamic world of textile and leather manufacturing, precision, speed, and reliability are crucial. Scantech Laser’s cutting-edge laser technologies are engineered to meet these critical demands, offering solutions that elevate the efficiency and quality of production processes in the textile and leather industries. From precise laser cutting and engraving to detailed marking and pattern making, our sophisticated systems provide unmatched precision and consistency. This ensures that every piece of fabric and leather meets the highest standards of quality, transforming traditional practices with modern innovation.

Pioneering Innovation in Textile & Leather with Laser Solutions

Our approach to the textile and leather industries enables us to anticipate their long-term advancements while focusing on current growth and development needs. Whether it’s creating intricate designs through advanced laser cutting techniques, enhancing product durability with precise laser engraving, or improving traceability with durable laser marking, Scantech Laser’s solutions are at the forefront of innovation in textile and leather production.

Leading Textile & Leather Innovation with Laser Solutions

As the sheet metal processing industry continues to evolve, Scantech Laser remains committed to supporting its growth with innovative, reliable, and efficient laser solutions. We are dedicated to understanding the unique challenges of this industry and providing the technologies that will drive its success in the years to come. Together, we’re not just meeting the needs of today; we’re propelling the sheet metal processing industry into the future.