laser marking in manufacturing Previously, while producers needed to mark a floor with a sample along with a barcode, photo, or text, they needed to pick out among conventional engraving or display printing. These processes, though, had been costly, nonpermanent, and frequently broken parts. With the implementation of laser marking, though, engineers are capable of creating characters, numbers, or snapshots without compromising the parts. Instead of the usage of a bodily device to etch the floor or transmit ink, this technique makes use of a centered laser mild to supply damage-free, easy-to-examine marks. Laser marking has come to be a crucial part of the producing industry — assisting corporations to preserve song in their products, enhance quality, decrease counterfeiting, and more. To assist apprehend the capacity in the back of this technology, we’ve laid out the advantages of laser marking in manufacturing.

It’s easy and eco-friendly

Other marking processes, together with inkjet or chemical etching, use inks and chemical substances for their marking — which now no longer handiest are costly consumables for the business, however, have a bad impact on the environment. Laser marking, on the alternative hand, does now no longer use any consumables — making it easy, low-priced, and electricity efficient. It additionally removes charges and downtime related to cleaning, solving, or powering printers. While labels can peel off or emerge as broken over time, laser marking affords everlasting identity for components and does now no longer must be accomplished a couple of times. Because the technique is non-contact, laser marking guarantees easy processing with minimum contamination. Where printing structures will burn down the cloth with the aid of using marking, the damage-loose technique entails minimum or no cloth penetration.

Scantech Laser marking machines allows producers to observe federal law

Many federal corporations require a few forms of identity to conform to legal guidelines that uphold quality, traceability, and different protection standards. Automotive companies, for example, use element traceability to quickly decide whilst and wherein an element changed into produced withinside the case of an element failure — assisting in recalls. When it involves the clinical industry, the Food and Drug Administration calls for all clinical producers to encompass a completely unique tool identifier on gadget labels and packages. This UDI is a completely unique code that includes a tool identifier, which identifies the labeler and the model/version, and a manufacturing identifier, which represents numerous components together with an expiration date, serial-wide variety, and different codes. Similarly, the Federal Aviation Administration calls for aerospace engineers to encompass sure marking in propellers, engines, and different components. It’s as much as the FAA to decide which markings are required on every element (together with model, builder, and certification), however, they have to be marked with an accredited fireproof method.

Laser marking can join elements of the Industrial Internet of Things

Another one of the blessings of laser marking is the capacity to connect to the IoT. Previously, massive producers with more than one laser marking machine might manually add a brand new task whenever there has been a brand new order (which became a time-eating and inefficient process). Mecco Marking and Traceability evolved a machine to satisfy the wishes of clever producers via way of means of streamlining this process – connecting automation and laser marking to the IIoT. Mecco created a programmable good judgment controller that works as a clever board, permitting one manufacturing facility supervisor to handle more than one job or automation strains concurrently and remotely. “Historically, marking structures have now no longer been capable of talking at once with a PLC,” David Sweet, president of Mecco Marking & Traceability, explains. “It’s been a mission for producers who need to include automatic element marking into their processes. The Remote API—and its capacity for bi-directional communication—is a key gain for us. It has allowed us to do what we couldn’t do before: seamlessly join our clients’ PLCs with their laser marking devices.”

It minimizes counterfeit products

Counterfeiting has a large effect on the worldwide pharmaceutical industry — a plague that isn’t most effective illegal, however, has many social and monetary implications. It’s expected that 10 percent of the world’s pharmaceutical income is counterfeit products. Not most effective has this price of the industry $sixteen billion, however, it opens up a bridge for prepared crime and terrorism. Pharmaceutical producers are constrained in what kind of marking they are able to use. The marking should be tamper-evidence and clean to read, well matched with the surroundings, and can not modify the product. Because of this, the maximum possible answer is laser inner engraving — a comparable technique that leaves a laser mark you could each see and feel. “The current improvement of industrial-magnificence ultrafast lasers allow inner marking with no harm to the container,” Eric Mottay of LIA Today says. “Because of the extraordinarily excessive optical depth and really quick pulse period brought through ultrafast lasers, there may be no warmth dissipation at some stage in the interplay technique, this means that there may be no micro-crack formation. Therefore, because the man or woman spots may be made very small, it’s also feasible to reap simply invisible marking, and but to assure dependable analyzing beneath neath right lighting.”

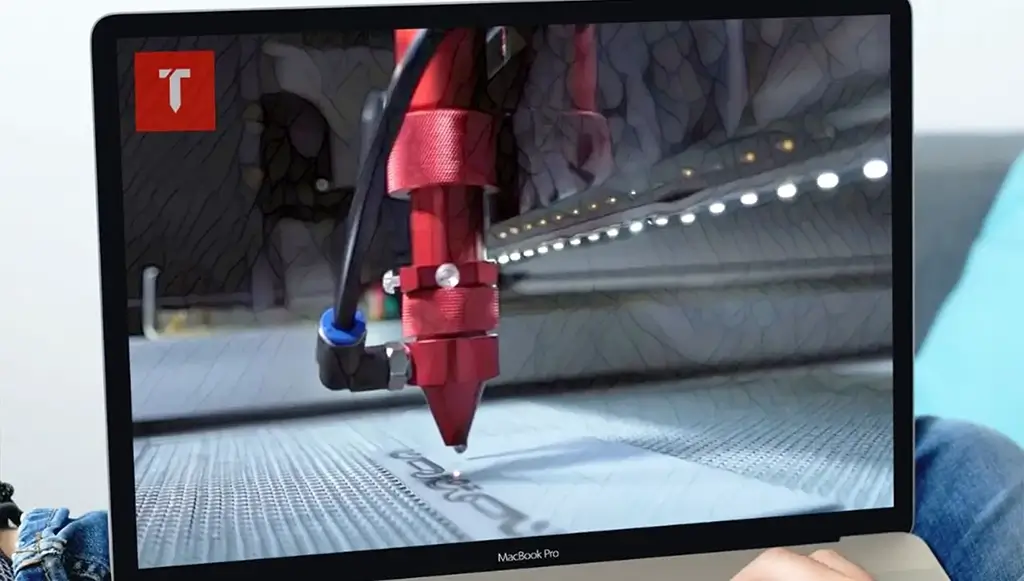

Laser marking gives the best result

With laser marking, there’s no want to etch a product or transmit ink onto the surface. Instead, laser mild is targeted onto a fabric to supply damage-loose marks. Here at Scantech Laser, we use Scantech LaserMark, One gain of this device is its beam quality, which ends up in a smaller spot length of the laser.

The small spot length, at the side of quick pulses, produces excessive height electricity that is useful in deep marking with crisp, clean marks and small characters. Laser marking in production: What’s next? What advantages of laser marking in production have you ever found? What have you ever discovered approximately the destiny of this technology? Let us understand with the aid of using tweeting us at @scantechlaser