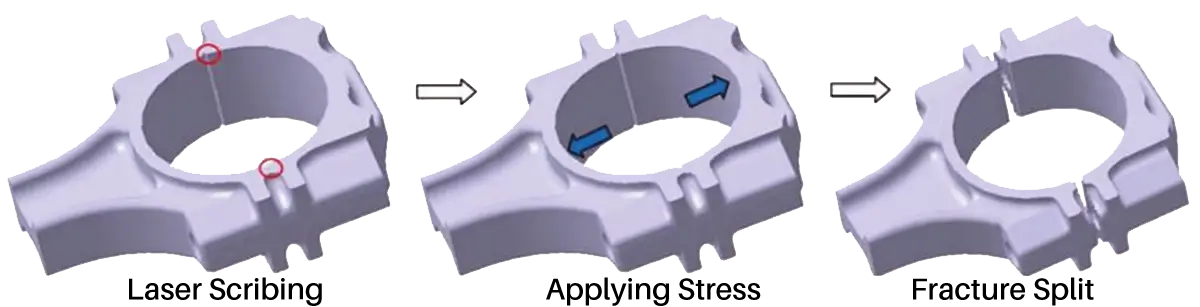

The laser scribing process allows for precise measurements and markings to be made on the connecting rod, which is important for ensuring that the connecting rod is manufactured to the correct specifications. This can help to improve the performance and longevity of the engine.

Laser scribing is also a fast and efficient process, which can increase production speeds and reduce costs. The process is also clean and doesn’t produce any fumes or other pollutants.

Laser scribing can be used to make a wide variety of markings on the connecting rod, including measurements, part numbers, and even company logos. It can also be used to make precise cuts on the connecting rod, such as for drilling oil passages or creating grooves for bearings.

However, the cost of the laser scribing equipment is relatively high, and the process requires highly trained operators.

Overall, connecting rod laser scribing is a highly effective method for making precise markings and cuts on connecting rods, offering precision, speed, and versatility. It is expected to be more and more popular in the internal combustion engine manufacturing industry in the future.

What is laser scribing?

Laser scribing is a process that uses a laser to create a precise, detailed line or shape on a surface. It is a fast and accurate way to create small, precise objects or patterns.

The laser is used to burn a precise line or shape on the surface. The heat from the laser creates a smooth, clean line or shape. Some benefits of laser scribing include the ability to create small, precise objects or patterns. It is also a fast and accurate way to create a smooth, clean line or shape.

How does Scantech laser scribing work?

The laser is used to burn a precise line or shape on the surface. The heat from the laser creates a smooth, clean line or shape. Some benefits of laser scribing include the ability to create small, precise objects or patterns. It is also a fast and accurate way to create a smooth, clean line or shape.